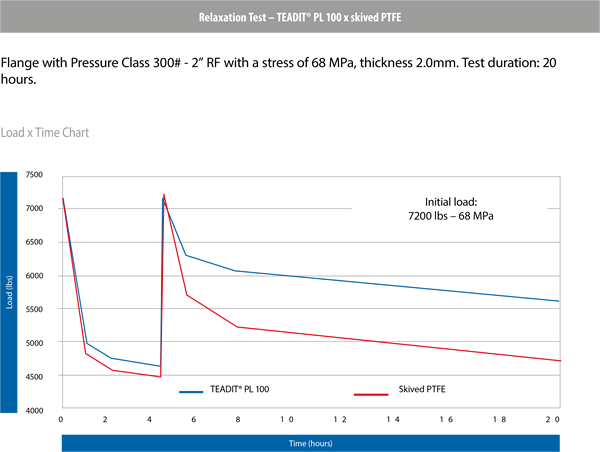

Flanges with pressure class 300# – 2” RF and stress of 68 MPa, thickness of 2.0mm

Test duration: 20 hours

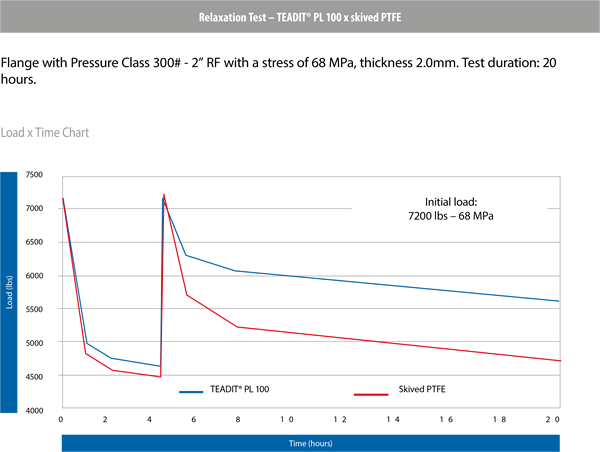

Flanges with pressure class 300# – 2” RF and stress of 68 MPa, thickness of 2.0mm

Test duration: 20 hours

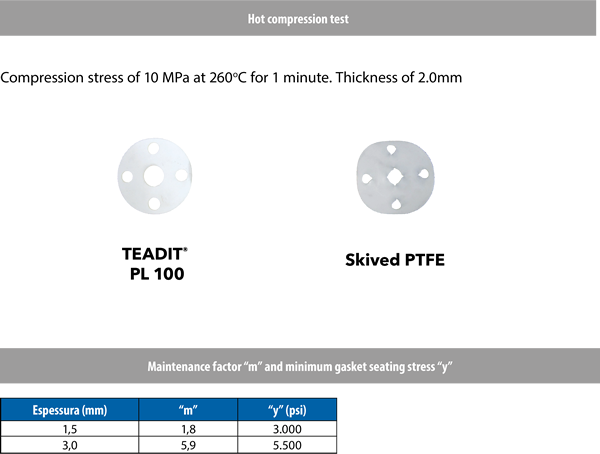

Compression stress of 10 MPa at 260ºC for 1 minute. Thickness of 2.0mm

| Operating parameters | TEADIT® PL100 |

|---|---|

| Maximum temperature (ºC) | 260 |

| Minimum temperature (ºC) | -268 |

| Maximum pressure (bar) | 55 |

| pH | 0-14 |

| Pressure x Temperature | bar x ºC |

| Thickness of 1,5 mm | 12.000 |

| Thickness of 3,0 mm | 8.600 |

| Sheet size | 1.500 x 1.500 mm |

| Available thickness | 1.5 , 2.0 and 3.0 mm (other upon request) |

| Thickness (mm) | “m” | “y” (psi) |

|---|---|---|

| 1.5 | 1.8 | 3.000 |

| 3.0 | 5.9 | 5.500 |

The factors “m” and “y” of a gasket are important parameters to be considered when calculating the torque of a sealing gasket. ASME Code Section VIII Division 1 Appendix 2 defines “m” as the gasket maintenance factor (always a dimensionless constant) and “y” as the gasket minimum seating stress. Although ASME provides generic values for the “m” and “y” factors, they can also be determined experimentally for each gasket material. This can be done through the analysis of laboratory results related to the inherent characteristics of each specific material, according to the criteria established by the manufacturer.

TEADIT® 25BI CASE HISTORY

2238-OX Case History

Teadit 24SH – Spiral Heat Exchanger Case History

Teadit 2235 - Steam Valves

TEADIT 24SH - Electrolytic Nickel Plant

TEADIT® 2005 – Harsh Chemical Agitator CASE HISTORY

24SH - Seawater Pumps

NA1100 Spiral Heat Exchanger Case History

TEADIT GR1700 CASE HISTORY

TEADIT® 2236 Fugitive Emissions Case History

Phone: +43 5332 74000

E-mail: austria@teadit.com