-

PTFE and expanded PTFE products

-

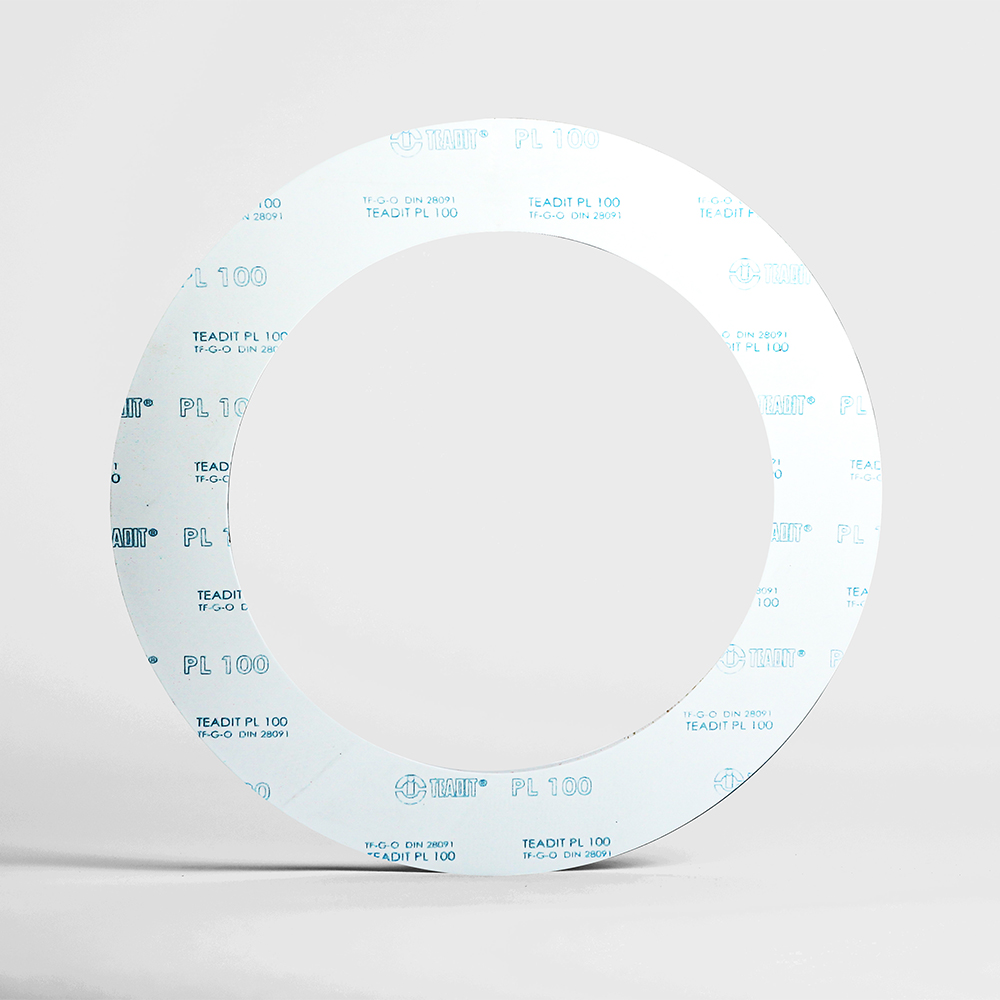

TEADIT® PL 100

PL100

-

TEADIT 25 BI

100 % multidirectional expanded PTFE Tape

-

TEADIT 24 BB

100 % monoaxial expanded PTFE wide Tape

-

TEADIT 24 B

100 % monoaxial expanded PTFE Tape

-

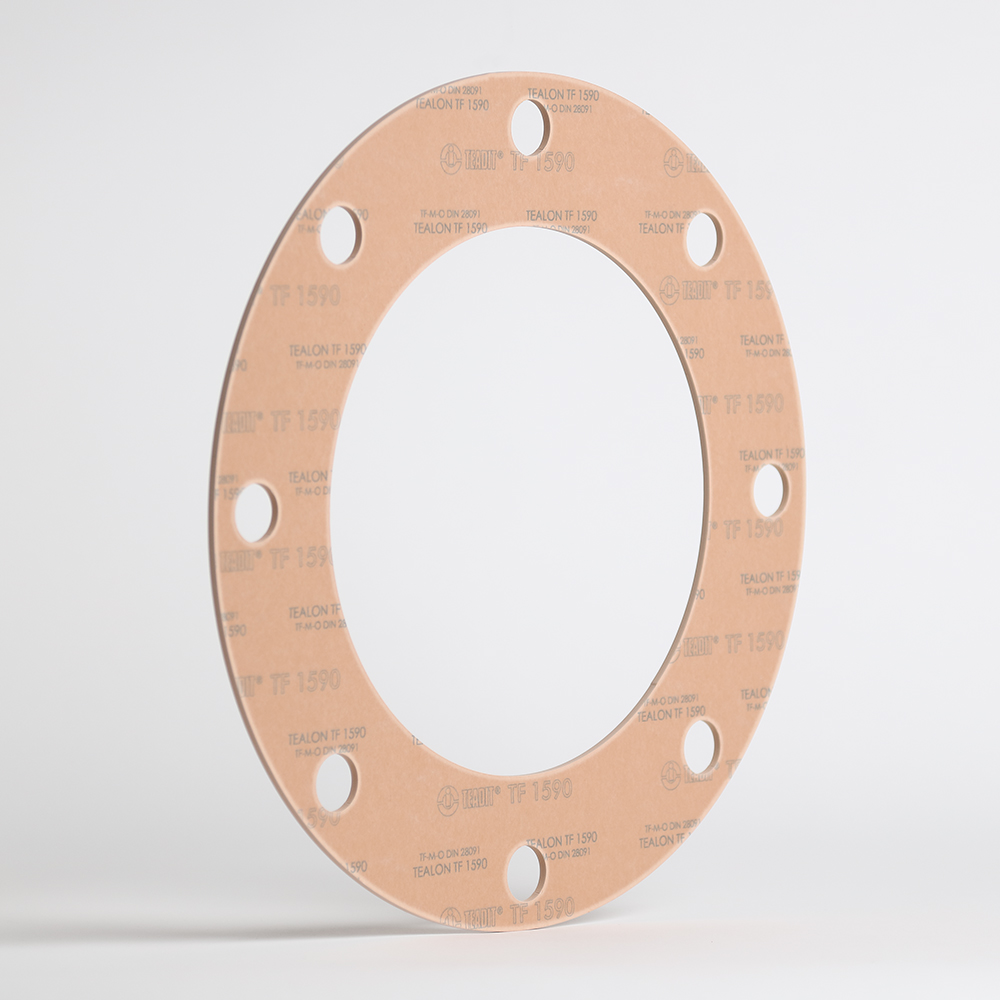

TEALON TF 1590

Restructure PTFE with Silica

-

TEALON TF 1580

Restructure PTFE with Barium Sulfate

-

TEALON TF 1570

Restructure PTFE with Glass Spheres

-

TEADIT 28 LS-LE

high pure ePTFE gasket with diffusion barrier

-

TEADIT 30 SH

100 % ePTFE gasket sheet

-

TEADIT 24 SH

100 % ePTFE gasket sheet

-

-

Compressed fiber sheets

-

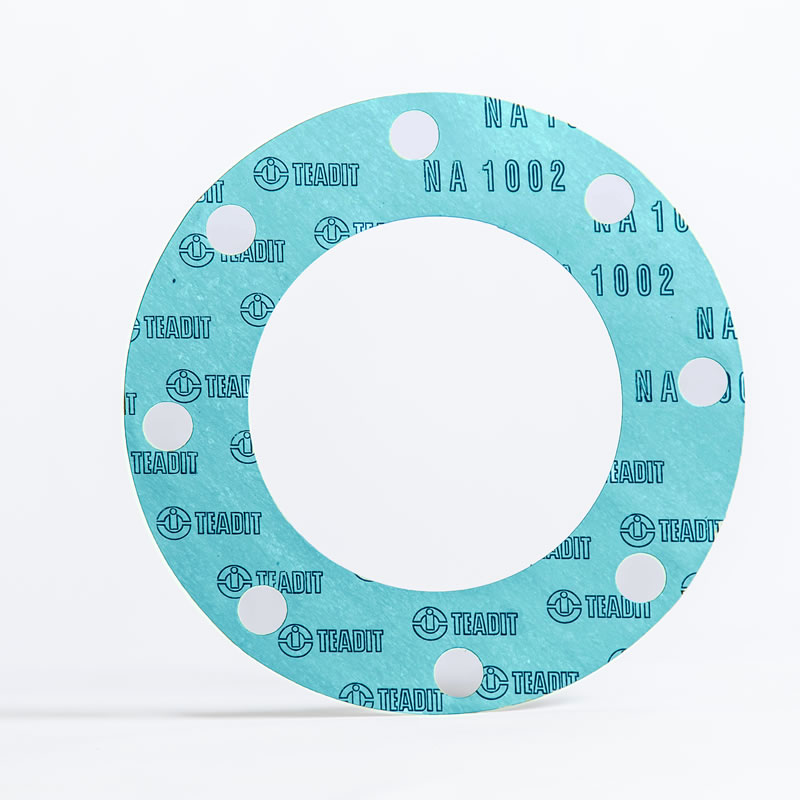

TEADIT NA 1002EU

high-end compressed non asbestos sheet material made of aramid fibers and bonded with NBR

-

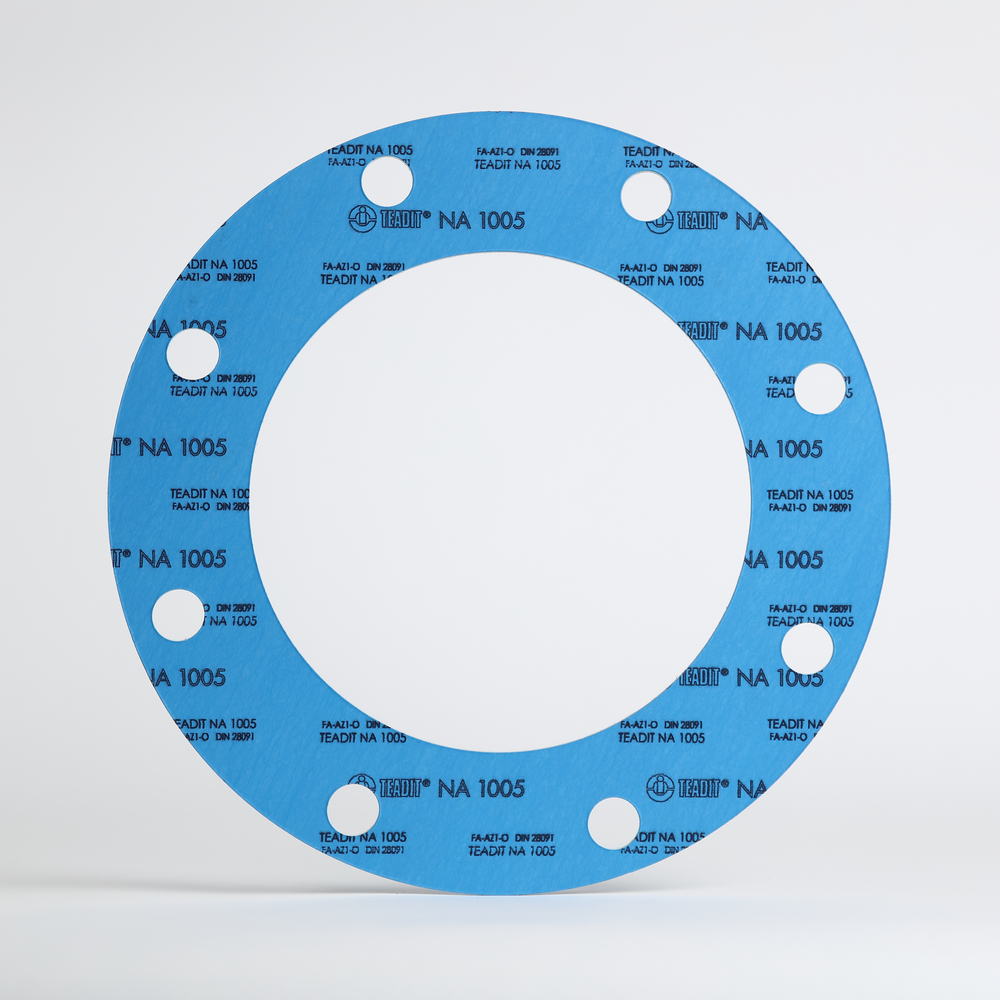

TEADIT NA 1005

compressed non-asbestos sheet material produced from a blend of aramid and other synthetic fibers bonded with NBR

-

TEADIT NA 1006

compressed non-asbestos sheet material

-

TEADIT NA 1122

compressed non-asbestos sheet material with inorganic fibres, special fillers, bonded with NBR

-

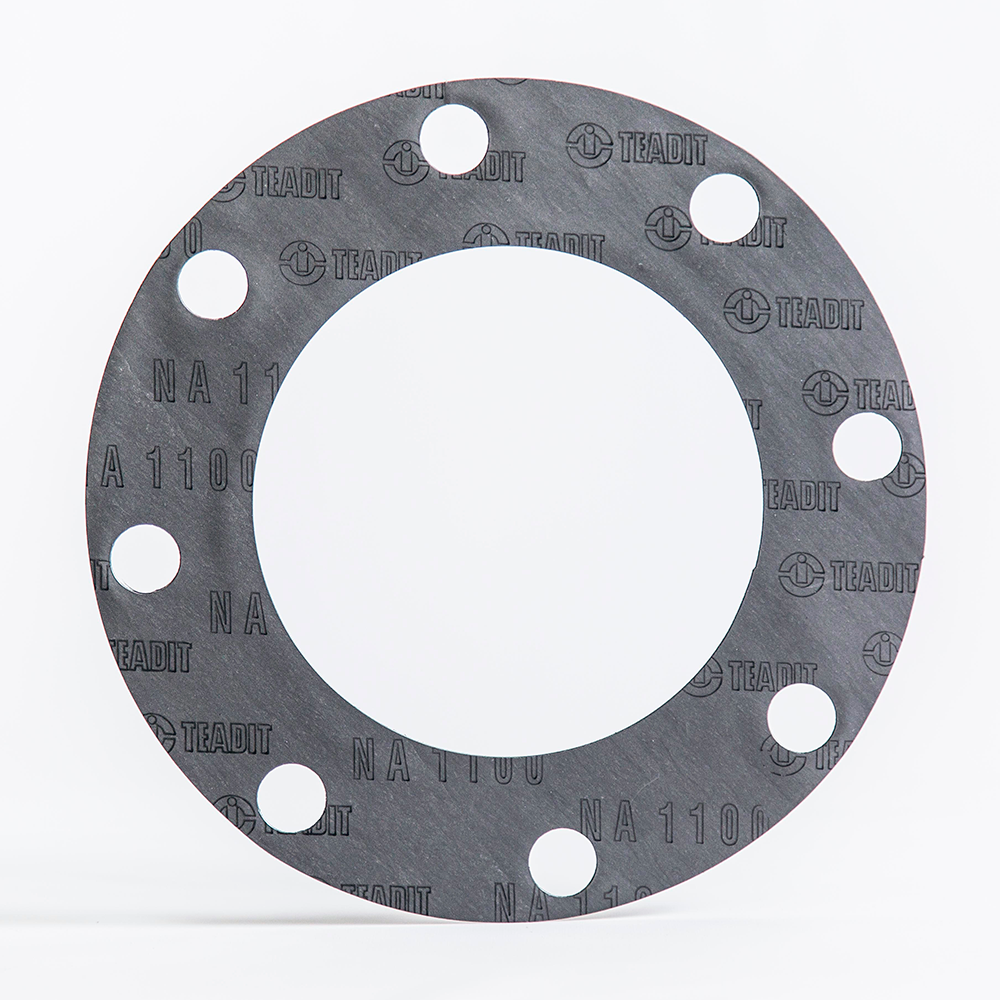

TEADIT NA 1100

universal compressed non-asbestos sheet material manufactured from graphite and carbon fibre, bonded with NBR

-

-

Graphite products

-

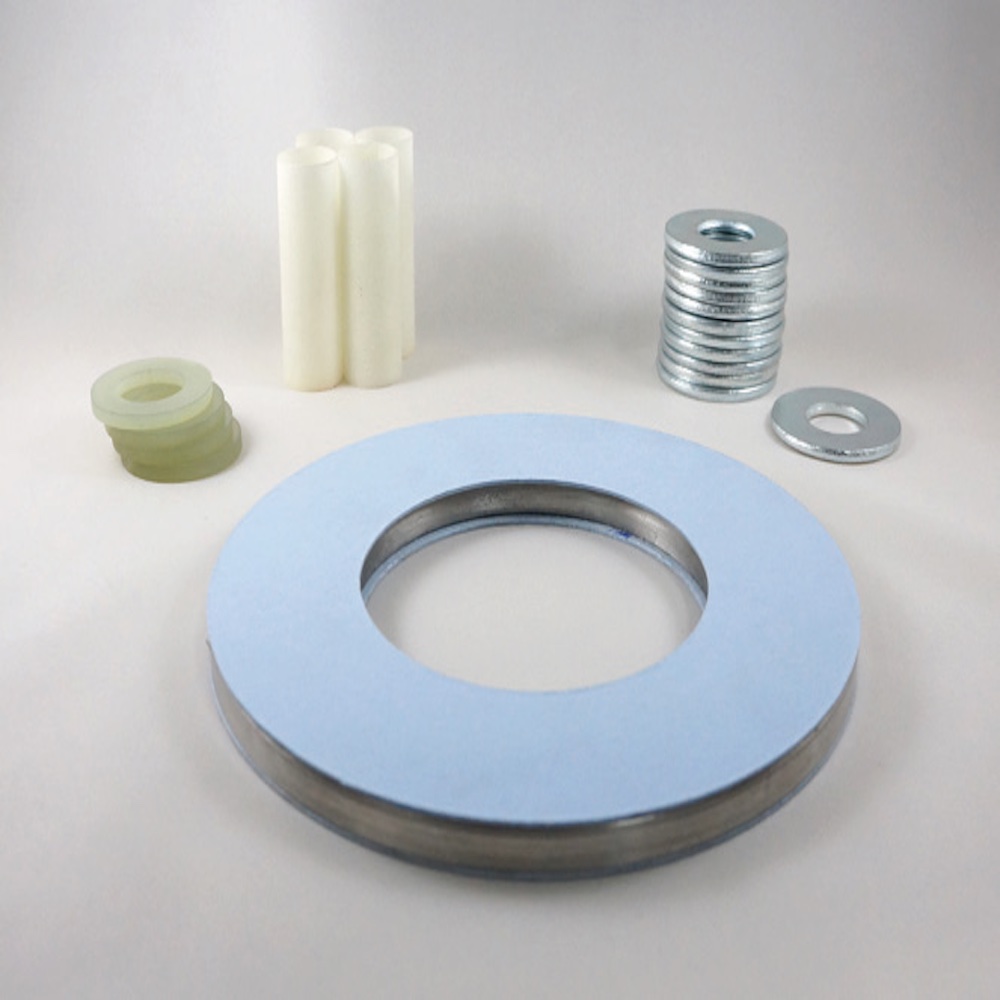

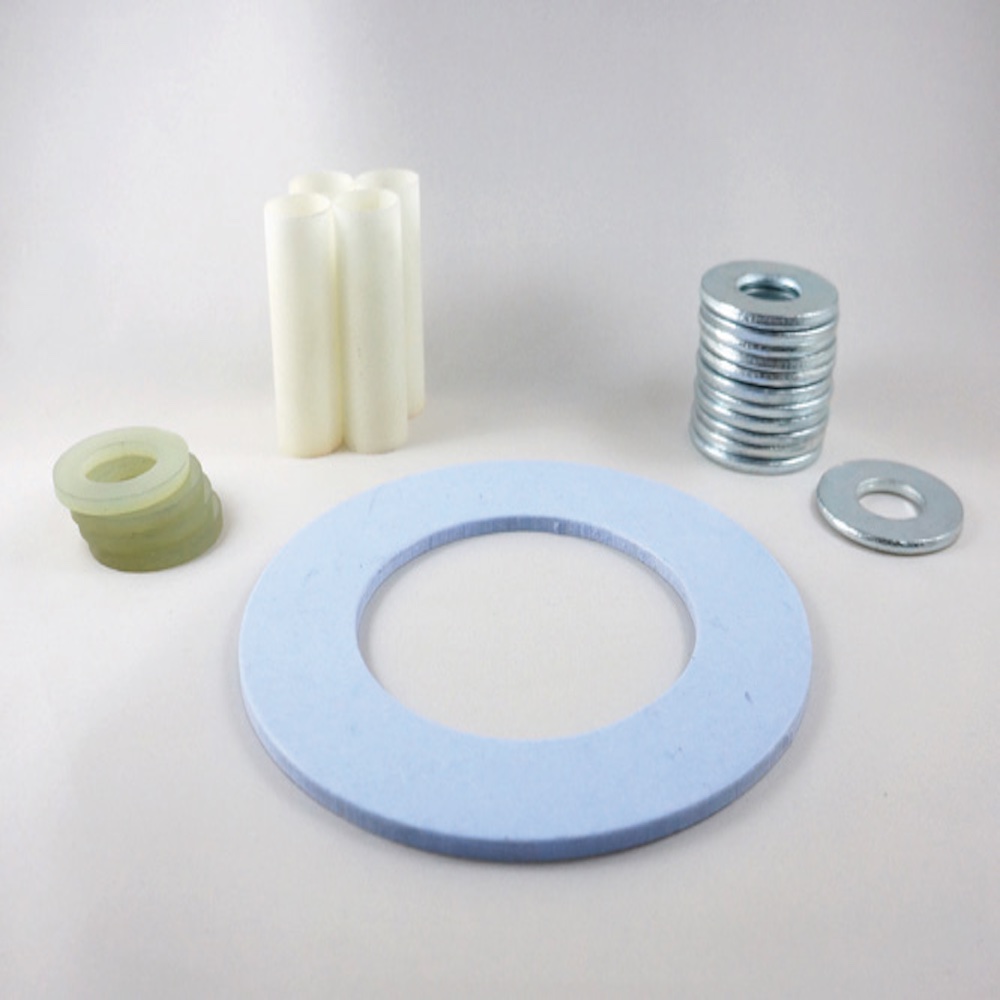

ELECTRON™ Electrical Isolation Gasket

The TEADIT ELECTRON™ gasket kit was developed to meet dielectric/cathodic protection needs and specifications in industries ranging from the most basic to the most demanding processes, guaranteeing a high level of sealability in flanges. The products offered in this market for such applications are often manufactured from phenolic resins, epoxy, rubber, etc.- materials that may present limitations when considering the growing mechanical and chemical performance demands of this industry. The ELECTRON™ gasket is more reliable and functional than these gaskets, in typical flanges, allowing for a higher degree of compression. The TEADIT ELECTRON™ Electrical Isolation Gaskets are included in our insulating kits. These kits are composed of a sealing gasket, insulating washers, metal washers, and insulating sleeves (as shown in the picture). These kits are used to prevent the electrochemical corrosion frequently observed in metal pipelines using flanges with different materials or underground pipes. They are typically used in refineries, oil pipelines, gas pipelines, chemical plants, and particularly in offshore units such as oil platforms.

-

Compression packing

-

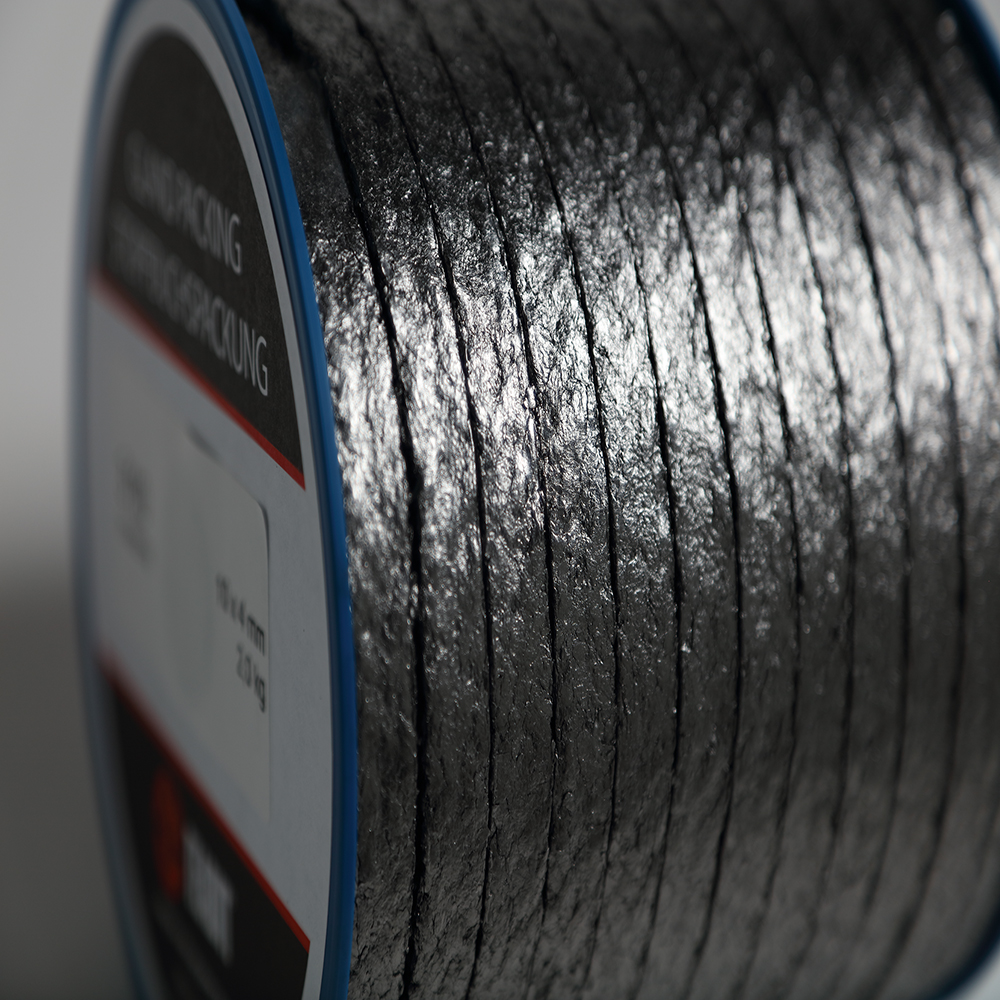

TEADIT Style 3110

braided tube and folded flat expanded, flexible graphite

-

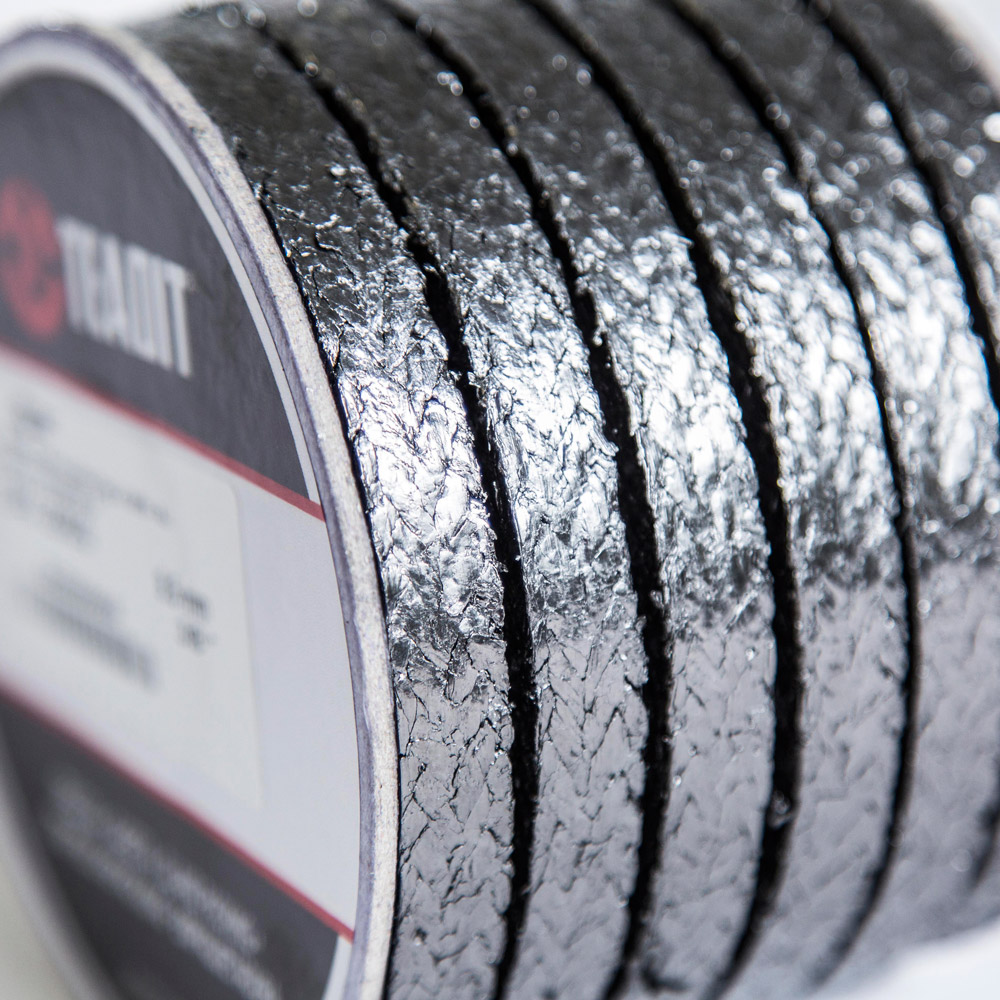

TEADIT Style 2001

Diagonally braided pure graphite yarn, treated with corrosion inhibitor and pure graphite powder

-

TEADIT Style 2000

Diagonally braided construction of pure, expanded flexible graphite-yarn

-

TEADIT Style 2422

Diagonally braided natural Ramie fibre and impregnated with a PTFE-compound

-

TEADIT Style 2044

Diagonally braided aramid staple fibre yarn, impregnated with PTFE and a silicone-free lubricant

-

TEADIT Style 2030

diagonally braided from DuPont NOMEX yarn, impregnated with PTFE-dispersion, lubricated with an inert mineral oil

-

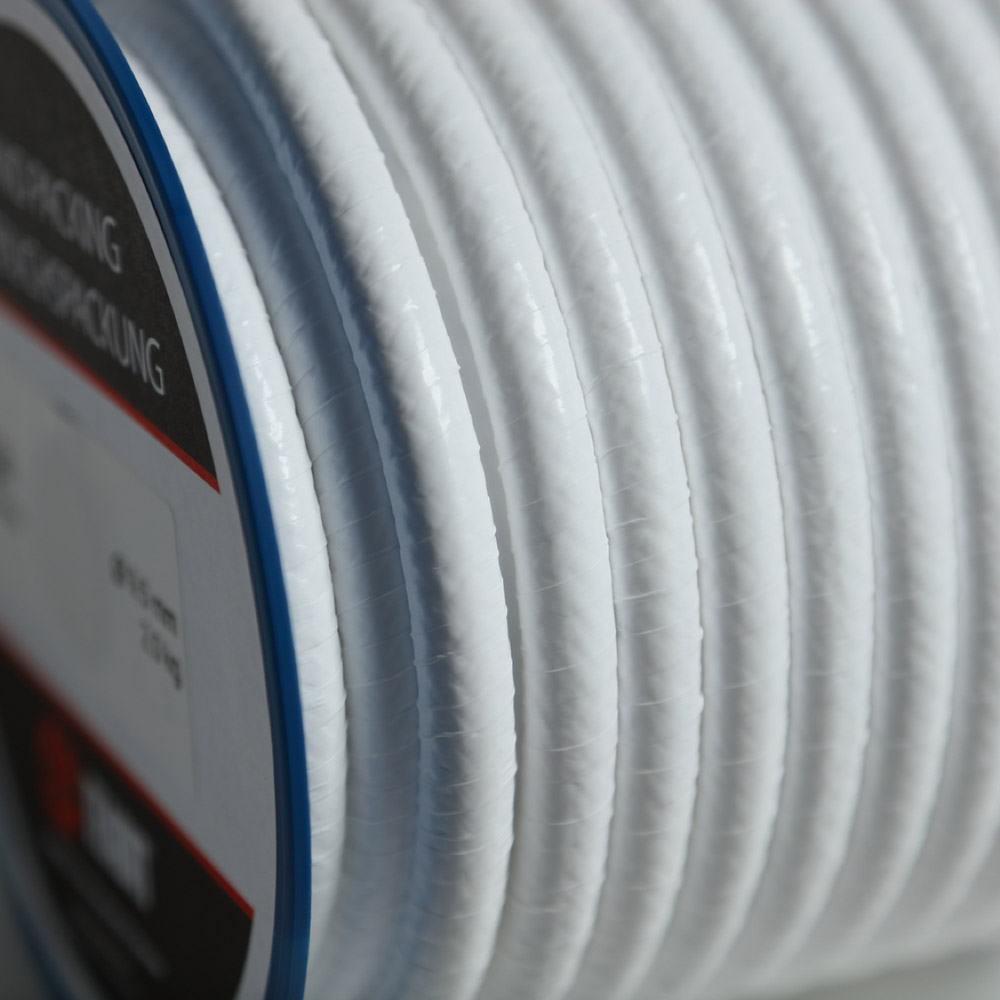

TEADIT Style 2124

braided in round cross sections 100 % pure PTFE-yarns and wrapped in an additional layer of PTFE-tapes

-

TEADIT Style 2007

Diagonally braided expanded PTFE-yarn with incorporated graphite, lubricated with silicone oil

-

TEADIT Style 2017

Diagonally braided PTFE yarn with incorporated graphite, reinforced at the corners with continuous Aramid yarn, lubricated with silicone oil

-

TEADIT Style 2006 FDA

diagonally braided expanded PTFE yarn treated with mineral oil

-