Refining

Teadit’s Research and Development department designs specific products to meet the growing demand of the Refining sector by constantly seeking new solutions for the most stringent requirements in this segment. Teadit products are prepared to perform with excellence, ensuring the good performance, safety and durability of the operation even under the most severe conditions of service.

TEADIT products recommended for this market are:

– TEADIT Packing Style 2236*

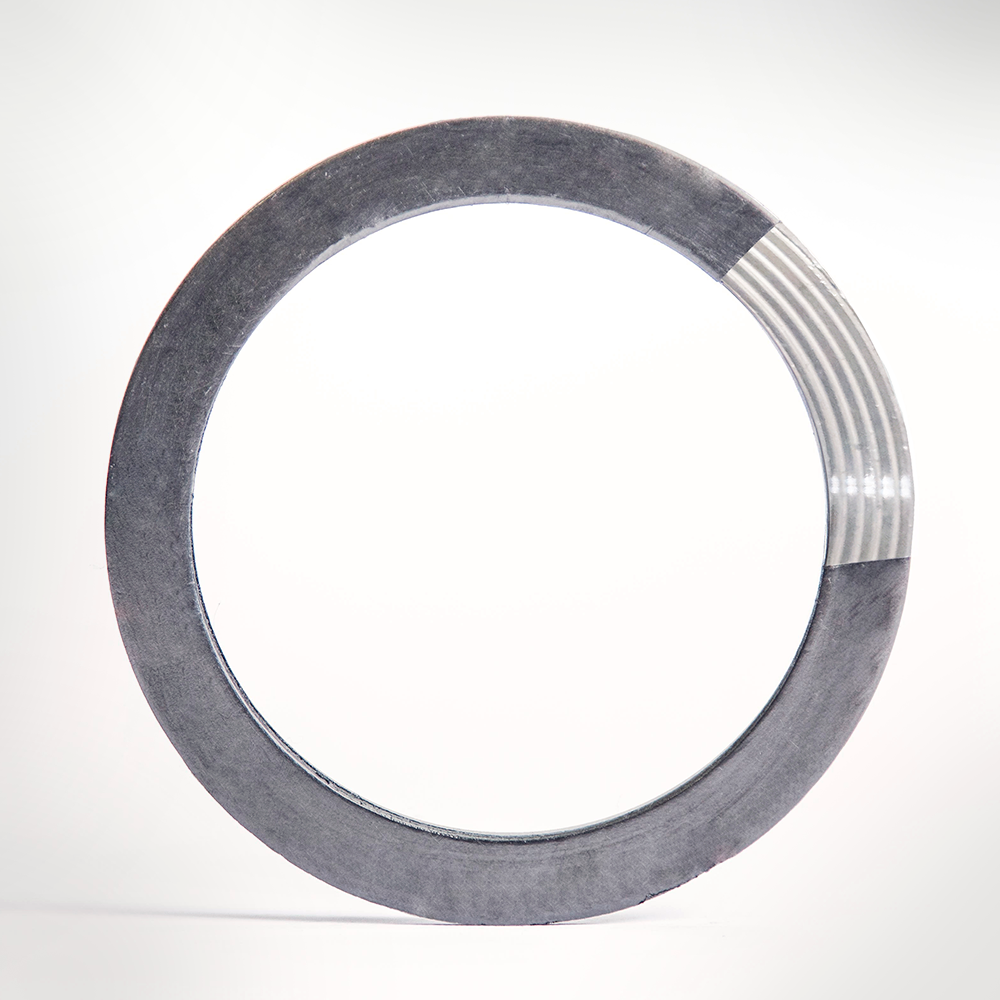

– Camprofile*

– Spiral Wound 913M*

– 905 Metalbest*

*Please click on the image to the right to access the product.