Efficient and effective bolted flange joint installations are pivotal for minimizing downtime and maximizing productivity in industrial plants. The ASME PCC-1-2019 Tightening Method recommends a minimum of four hours of dwell time before retightening the bolts to restore short-term creep relaxation and embedment losses. Research has shown that dwell time, which is defined as the period between initial torque and a post-installation retorque, is a crucial interval for gasket performance optimization. However, given the many variables that impact flange joint reliability, particularly the differences between various gasket technologies, natural questions concerning dwell time arise. Can this four-hour installation dwell time be reduced without compromising gasket performance? Is four hours the optimal amount of time to wait to retorque, regardless of gasket selection? Therefore, there is value in investigating the process to seek answers to the previously highlighted questions, and others like them.

In the context of bolted flanged joint installations, it is important to note that the significance of dwell time varies across gasket technologies. While ASME PCC-1-2019 emphasizes the importance of a minimum four hour dwell time to address short-term creep relaxation and embedment losses, it is essential to recognize that this practice is not universally applicable to all gasket technologies. Despite its crucial role, the implementation of a four hour dwell time can contribute to increased overall downtime during maintenance activities, incurring a (sometimes significant) cost.

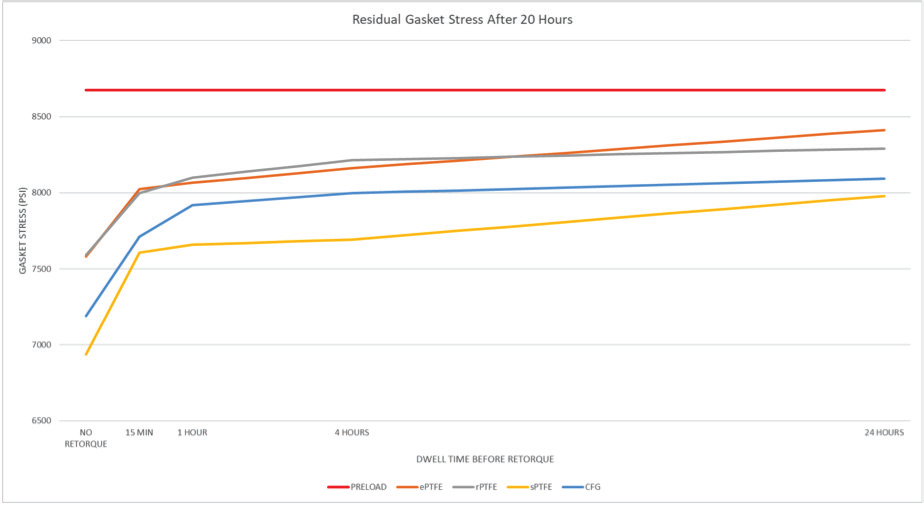

Figure 1.

Figure 1.A study published by three engineers from Teadit, Carlos D. Girão, Igor Meira, and José Carlos Veiga in 2021, sought to investigate the significance of dwell time in bolted flanged joint installations to determine if the amount of time between installation and retorque could be minimized and/or optimized for different gasket materials. In their study, Girão, Meira, and Veiga explored varying dwell times (15 minutes, one hour, four hours, and 24 hours) across different gasket styles and materials, including PTFE, Compressed Fiber Sheet Gaskets (CFG), and metallic gaskets. The aim was clear: to strike a balance between minimizing plant downtime and ensuring gasket effectiveness.

Experiment Setup

Their study employed an NPS 4, class 150 ASME B16.5 flange outfitted with eight strain-gauged bolts, correlating bolt elongation with applied stress. This comprehensive approach allowed them to measure the impact of different dwell times on joint relaxation and bolt preload loss. The goal was to determine, based on the different gasket types, the point at which dwell time begins producing diminishing gains. This would hopefully provide insight for plant personnel seeking to minimize downtime.The gaskets were installed per ASME guidelines and a retorque was applied at the determined dwell times. After 20 hours, the retained gasket stress was measured to determine the overall loss from preload. A control sample that was not retorqued at all was used as a base-line to measure against.

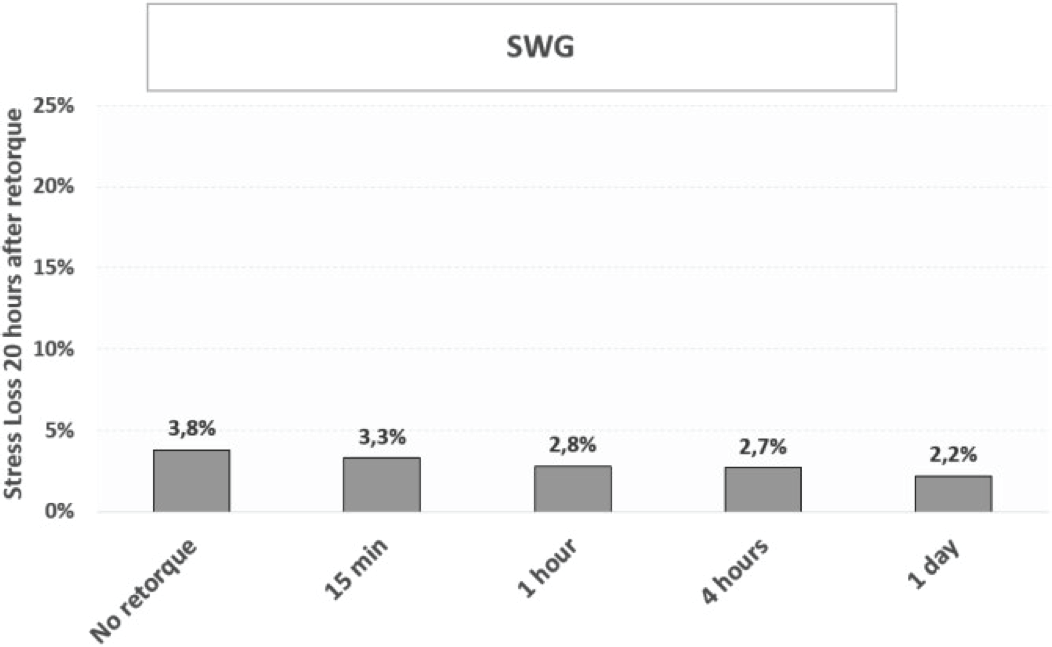

Figure 2.

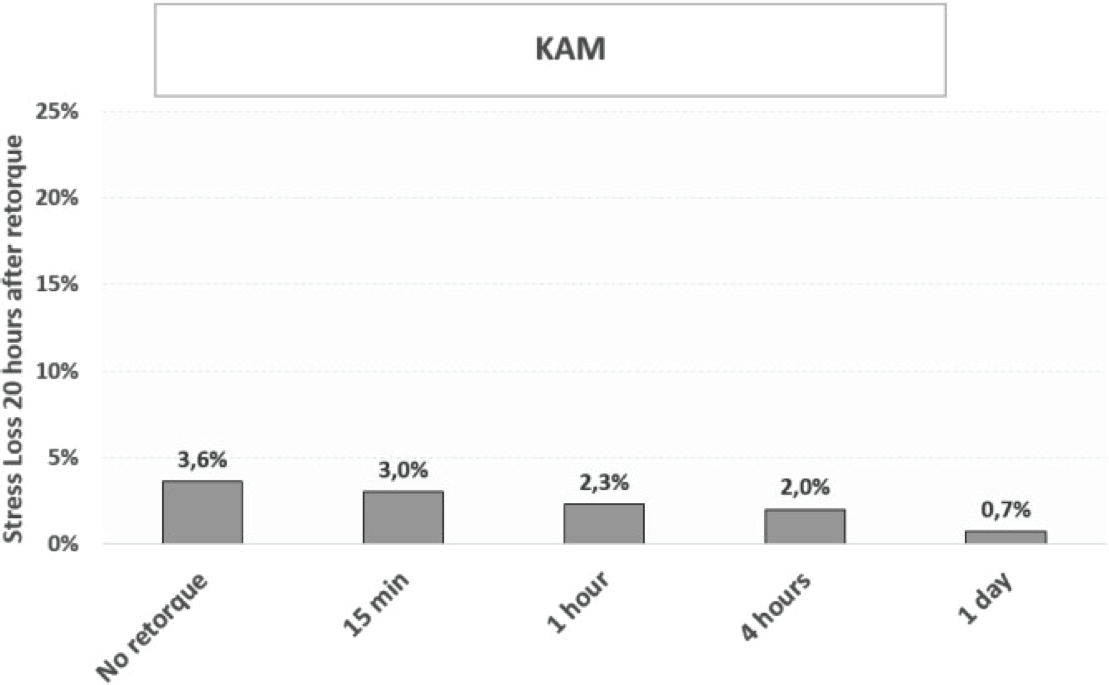

Figure 2. Figure 3.

Figure 3.Gasket Material Matters

The results of their study revealed intriguing insights into the role of dwell time, particularly in relationship to gasket type, as the impact varied among the tested materials. For instance, in the case of expanded PTFE (ePTFE), a 15-minute dwell time demonstrated a significant improvement in gasket stress.Extending the dwell time to one hour, then four hours, and eventually to 24 hours produced a nearly consistent incremental increase (i.e. constant trendline slope), however the most advantage seen of a retorque is after 15 minutes consistent incremental increase (i.e. constant trend-line slope). Conversely, restructured PTFE (rPTFE) showed steeper increases at one hour and, to a slightly lesser extent, four hours before flattening out dramatically, indicating very little benefit in extending dwell time beyond the ASME recommendations. Expanded PTFE boasted the lowest overall preload loss with retorque at 24 hours among the ‘soft’ gaskets tested.

Skived PTFE (sPTFE), a material inherently known to be susceptible to high levels of relaxation resulting in preload loss, experienced the highest level of loss (20% loss of total preload) without retorquing. However, the difference in the results between dwell times of 15 minutes (12.3% loss), one hour (11.7% loss), and four hours (11.3% loss) was negligible. This indicates that skived PTFE materials relax and lose their load quickly after installation, so retorquing after 15 minutes could be a viable option compared to waiting the recommended 4 hours per ASME PCC-1. Notably, it is worth mentioning that ePTFE and rPTFE exhibit the same amount of relaxation after 15 minutes of dwell time as virgin PTFE does after 24 hours. Extending the dwell time to a full 24 hours does dramatically decrease the overall preload loss. Likewise, compressed fiber gaskets (CFG) exhibited only slight overall improvements from one hour to 24 hours, suggesting that for CFG gaskets, a one hour dwell time could be a pragmatic compromise to expedite operations without sacrificing overall performance.

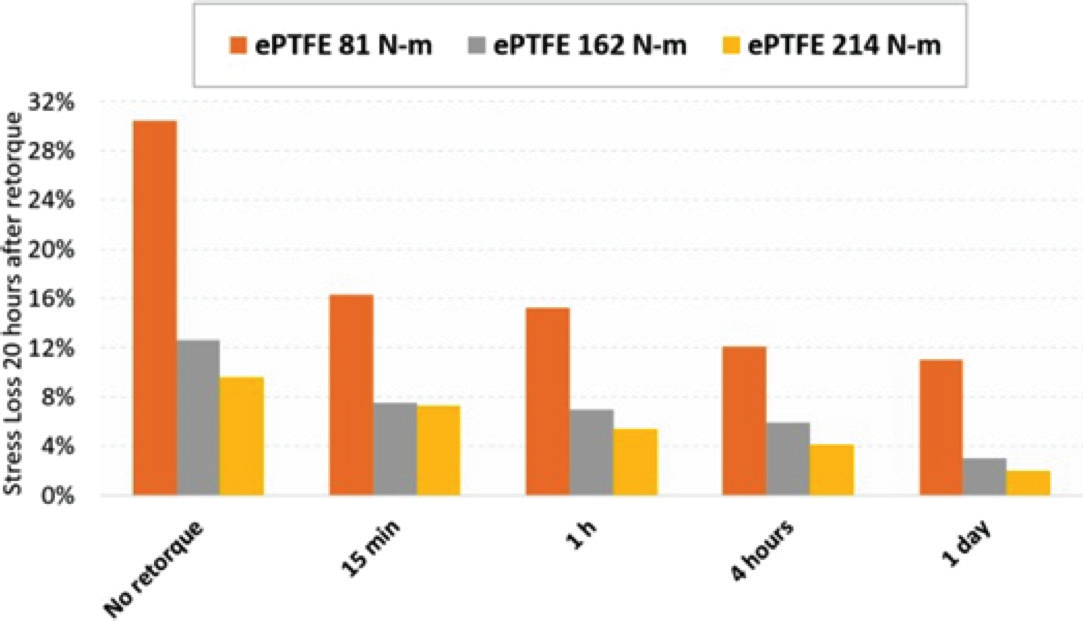

Figure 4.

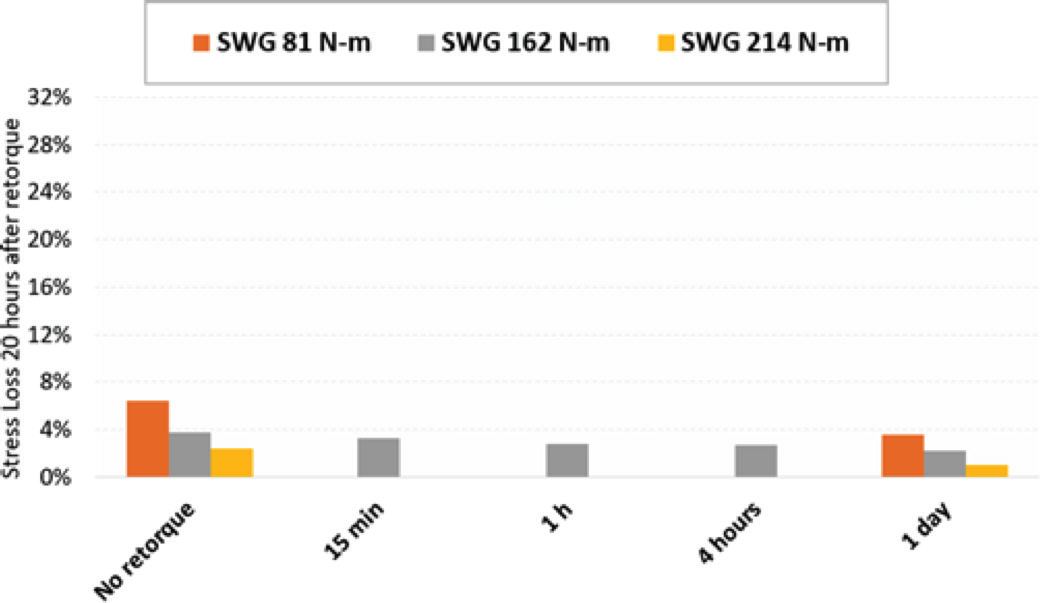

Figure 4.Metallic gaskets, inherently less susceptible to relaxation effects, as indicated by the study, showed only marginal stress loss differences across various dwell times (including no retorque at all) at ambient conditions. It is important to note that Figure 2 and 3 illustrate this phenomenon for spiral wound gaskets (SWG) and kamprofied gaskets (KAM) under these conditions. Kamprofiled gaskets, with a 24-hour dwell time be- fore retorque, exhibit less than 1% over- all preload loss, making them one of the tightest overall sealing options. However, it is essential to consider that relaxation is influenced by temperature, and these results reflect ambient conditions.

Additionally, the study looked at the impact of under and over-tightening on relaxation and load retention for two of the materials, spiral wound gaskets and ePTFE. In Figure 4, one can see the ePT- FE stress loss results for torque levels of 60 ft-lbs (81 N-m), 120 ft-lbs (162 N-m), and 158 ft-lbs (214 N-m). These torques equate to approximately 37%, 75%, and 98% of bolt yield, respectively.

Notably, lower gasket stress significantly impacts relaxation. In the case of ePTFE (a high-stress relaxation gasket), when under-tightened the stress loss surged to 2.4 times that of the baseline level. On the other hand, in cases of over-tightening, the stress loss for the baseline and over-tightened states showed relatively minor differences, suggesting that beyond a certain stress threshold, relaxation becomes less pronounced. In all cases, the effect of dwell time followed similar trends, though differing in magnitude.

Of particular note is the significant decrease in load retention from no retorque to the 24 hour dwell time for the under-tightened state. Since industry research has shown that the overwhelming majority of industrial facilities do not follow proper torque and flange assembly best practices, resulting in under-tightened flanges, the value of a retorque, particularly on high-relaxation materials like PTFE, is made even more critical.

The spiral wound gasket (a low-load relaxation gasket) also performed as expected (Figure 5), showing a considerably lower impact on load retention when under or over-tightened, resulting in minimal differences in gasket stress concerning the retorque dwell time. As a result, not all of the dwell time intervals were tested for the additional torque levels.

Alternative Assembly Patterns: A Time-Saving Triumph

In their investigation, Girao, Meira, and Veiga also compared two ASME PCC-1 installation methods: the Legacy Cross- Pattern Numbering System and the Alternative Assembly Pattern #3. The difference in the results for load retention and dwell-time, even in the under and over-tightened states, were negligible; with the Alternative Pattern #3 slightly outperforming the Legacy Pattern. How- ever, the former, a more streamlined approach, proved to be approximately 45% faster in execution. This revelation underscores the potential for substantial time savings in plant maintenance operations during flange bolt-up. Figure 5.

Figure 5.Conclusion

The dwell time dilemma is a critical consideration in bolted flanged joint installations. The study done by Girão, Meira, and Veiga demonstrates that a one-size-fits-all approach to dwell time may not be optimal. Depending on gasket material and type, shorter dwell times, as brief as 15 minutes, can yield significant improvements in stress loss without compromising gasket performance. Additionally, in critical services, opting for a longer dwell time to minimize preload loss and maximize tightness could be worth considering, as well as utilizing gaskets that exhibit lower overall stress-relaxation.This research opens the door to further exploration. Investigating additional materials, such as rubber, and evaluating the impact of gasket installation stress for various gasket types could provide even deeper insights into the impact of dwell time. In their findings, Girão, Meira, and Veiga concluded that optimizing dwell time is not merely about expediting installations and reducing downtime; it is about enhancing the overall efficiency and reliability of industrial plant operations. Tailoring dwell time to specific gasket materials and styles presents a viable pathway to more effective maintenance operations and improved profitability, sustainability, and efficiency.

About the Author

About the Author