To achieve leak-free performance, understand what factors help improve gasket performance.

Learning Objectives

- Understand the critical role of gasket design and material selection in ensuring joint reliability, safety and emissions compliance across industrial applications.

- Identify key factors that influence sealing performance, including temperature resistance, pressure containment, chemical compatibility, vibration and environmental exposure.

- Apply best practices for gasket installation and maintenance to prevent common failure modes, improve system integrity and extend the service life of sealing systems.

Gasket Insights

- This article highlights how gasket reliability is central to plant safety, emissions control and operational efficiency, emphasizing that sealing success depends on material selection, joint design and disciplined installation practices.

- By treating gaskets as engineered components rather than commodities, facilities can significantly reduce failures, improve uptime and extend system reliability.

By Chris Morris and Angelica Pajkovic

In industrial environments, gasketed joint reliability often makes the difference between efficient operations and unplanned downtime. Whether in a refinery, chemical plant, power generation station or pulp and paper mill, sealing product performance plays a crucial role in the site’s overall reliability.

Gaskets are often given little consideration within the overall scope of maintenance operations. Everyone knows they need to have them, but the nuances of different types and materials and the pros and cons of each, are not well understood in many cases. Though gaskets are often thought of as simple and at times interchangeable components of a piping system, they are specifically and carefully engineered to maintain system pressure and contain process media while withstanding mechanical, thermal and chemical attack. Their success or failure directly impacts plant safety, emissions performance, product purity and mechanical integrity.

It is essential to recognize that gasket performance is not determined solely by the product itself, but by the interaction of the sealing material, the flange, the bolts, the operating conditions and the installation practices. When sealing considerations are properly evaluated and managed, the entire system benefits from improved performance and reliability.

Gasket Considerations During The Design Phase

Sealing failures rarely occur due to poor-quality gaskets. Most leaks that result in containment loss stem from insufficient design, incorrect installation or the selection of unsuitable materials. Therefore, it is important to consider these eight design factors for optimal gasket performance.

1. Temperature Resistance And Thermal Cycling

Gaskets must accommodate both steady-state operating temperatures and, when present, thermal and pressure cycles. In applications such as heat exchangers or reactors, process temperature changes can cause significant system movement, resulting in the loss of bolt preload and gasket stress.

Flexible graphite, for example, is a popular choice for applications running at higher temperatures (above 500°F). These gaskets are also highly compressible, allowing them to conform to flange surface imperfections.

Figure 1: Depiction of gasket material before being cut into gasket. Courtesy: TEADIT

However, flexible graphite sheet gasket materials generally exhibit limited recovery, meaning that once they are compressed, they do not rebound. Gasket recovery is critical in cycling applications and therefore is a primary consideration for these services. The use of graphite for facings and fillers in semi-metallic gaskets like spiral wounds or corrugated metal gaskets take advantage of the temperature resistance of the material, while at the same time adding robustness that leads to better recovery.

2. Pressure Containment

A properly selected gasket will typically withstand the system’s internal pressure while maintaining an effective seal over time. High-pressure systems often benefit from spiral-wound gaskets, which combine alternating wraps of metal winding with a soft filler material (often graphite).

Spiral-wound gaskets come in a variety of styles, with the most common being the industry standard pipe flange version that includes both an outer guide ring that centers the winding on the flange and an inner ring to resist inward radial buckling. The added benefit of the inner ring is that it stiffens the gasket preventing the windings from being easily over-compressed and increasing the gasket’s overall tightness and recovery.

Additionally, changes within the last decade to the American Society of Mechanical Engineers (ASME) B16.20: Metallic Gaskets for Pipe Flanges standard that governs spiral wound manufacturing have resulted in improved winding density which leads to better overall performance. Since the 2017 revisions, B16.20 spiral-wound gaskets have been designed to meet sealing performance thresholds.

3. Chemical Compatibility

Gasket material must be chemically compatible with the process media it is exposed to. Recognized for their ability to withstand harsh chemicals, polytetrafluoroethylene (PTFE)-based materials are an ideal choice for applications that use or are exposed to acids, caustics, solvents and aggressive hydrocarbons.

The chemical structure of the PTFE polymer allows the material to resist many of the common mechanisms that lead to chemically induced mechanical degradation of the material. Expanded PTFE (ePTFE) is highly conformable to irregular flange surfaces like those found in lined vessels and is a valuable option for applications where ultra-clean service or regulatory compliance is required. Blue, fawn and off-white restructured PTFE gaskets incorporate fillers like glass microspheres, silica and barium sulfate to reduce gasket creep, enabling their use in demanding chemical processing environments without sacrificing mechanical stability.

4. Vibration and Mechanical Movement

Sealing systems subjected to vibration, pipe stress or rotating equipment must be designed for joint flexibility. Materials with high recovery characteristics, damping and resistance to extrusion help maintain sealing performance under mechanical load variation. Some of these materials can conform to out-of-flat flanges while maintaining adequate sealing stress, reducing the likelihood of gasket failure.

5. Environmental Exposure

External factors, including ultraviolet exposure, weathering, aging and thermal shock, may influence material longevity. Engineers must evaluate the storage of gaskets and materials, as well as the installation environment in tandem with process conditions when selecting a sealing solution.

While a popular choice for many general service applications, elastomeric gaskets or gaskets that contain elastomeric binders are highly susceptible to these factors and care should be taken to ensure that these gaskets are suitable for installation. Signs of brittleness or cracking are clear indicators that the gasket is unfit for service.

Graphite and PTFE, on the other hand, perform reliably in a wide range of ambient environments with little to no impact on the gasket’s mechanical properties. However, advancements in coatings for rubber-based gasket materials, such as nonstick or anti-oxidation layers, have improved removal during maintenance and extended service life in harsh environments.

6. Material Selection Across Sealing Types

The material properties, such as chemical resistance, compressibility, thermal stability and creep relaxation, must align with the application’s operational environment to maintain sealing integrity and extend service life. The range of materials available today enables precise tailoring of gasket properties to application demands.

- Elastomers and rubber-based fiber sheets: Cost-effective for low-pressure systems, available in a variety of combinations.

- Virgin skived PTFE: Unfilled, clean and stable across a broad chemical range; suitable for sanitary, food-grade and pharmaceutical low temperature services.

- Restructured PTFE: This is filled PTFE with improved strength and reduced creep relaxation, ideal for dynamic thermal and pressure conditions.

- ePTFE: Compressible, chemically resistant and ideal for irregular flange surfaces.

- Flexible graphite: High-temperature performance with excellent stress relaxation and thermal conductivity.

- Metallic and semi-metallic gaskets: Spiral wound, kammprofile, corrugated metal and ring-type joint gaskets for high-pressure, high-load systems.

7. Application-Specific Engineering

Every sealing application is unique. Steam systems require materials with thermal stability. Chemical applications demand robust chemical resistance. Sanitary systems must comply with NSF/ANSI 61, FDA 21 CFR or USP Class VI standards.

Specialized manufacturers address this diversity by offering both standardized and custom-engineered sealing materials. Innovations such as specialized PTFE gaskets for glass-lined equipment and flange-isolation gasket kits for cathodic protection have enabled more precise solutions for challenging or niche applications.

8. Joint Design And Tolerances

Gasket selection must be coordinated with flange geometry, surface finish and assembly practices. Flanges must be flat, parallel and free from damage. The fasteners generate the clamping forces that load the gasket and create a seal and are therefore a critical component in flange joint reliability. Bolt loading, performed with a calibrated tool, must be uniform and within calculated torque values.

Design engineers should model joint stress and relaxation behavior under load and thermal conditions to ensure long-term sealing integrity. Innovative joint modeling software and digital training tools have contributed to more consistent field performance and easier training of maintenance teams.

Installation Discipline And Failure Prevention For Gaskets

A gasket is designed to form a static seal by occupying the tiny irregularities between flange faces and distributing compressive load evenly across its surface. However, the correct installation, in addition to suitable material and design selection, is crucial for maintaining that seal over time.

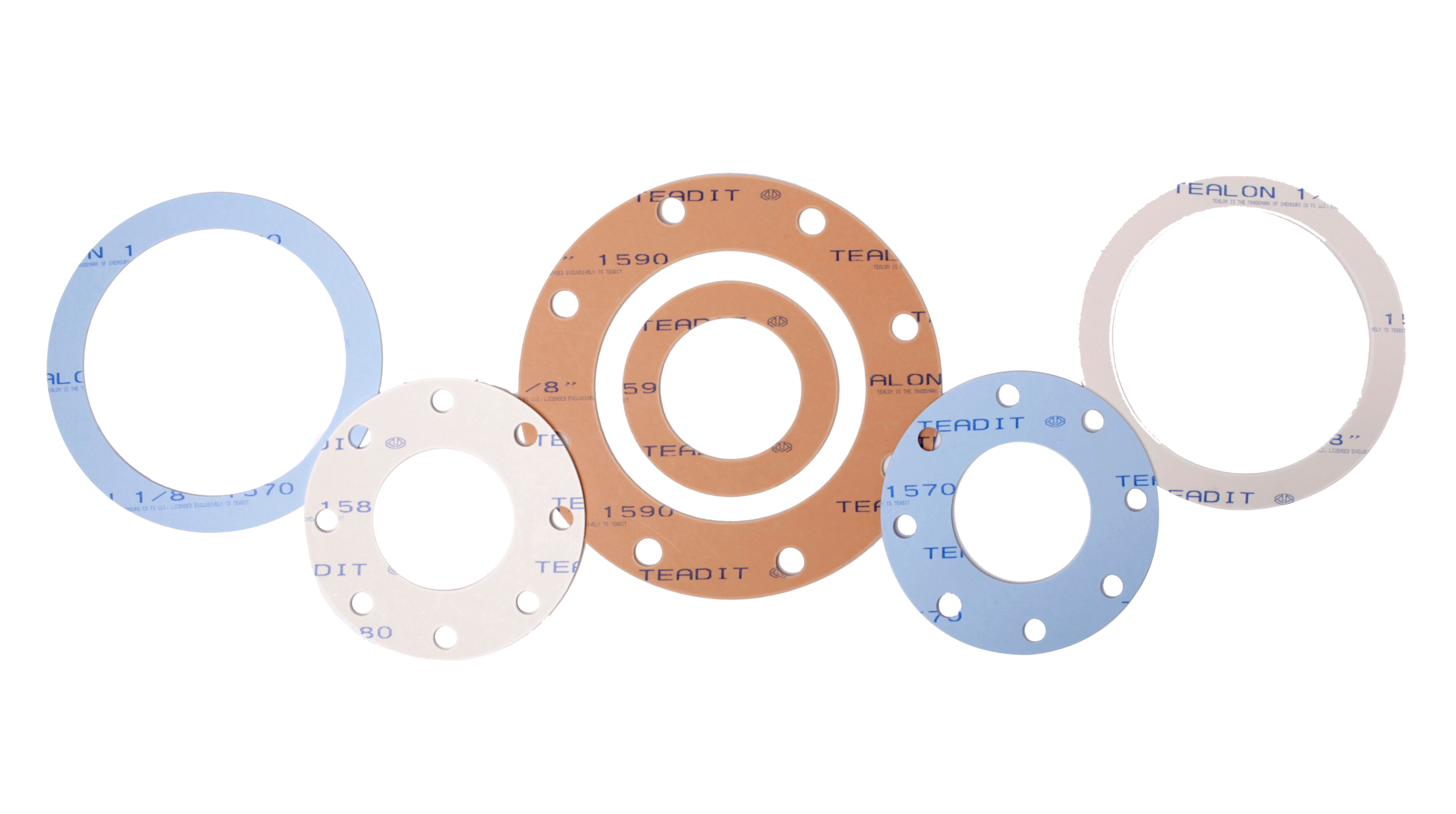

Figure 2: Example of gaskets made from a variety of polytetrafluoroethylene (PTFE)-based materials. Courtesy: TEADIT

Proper installation ensures that the gasket deforms as intended, maintains sufficient stress under operational pressure and temperature and prevents the loss of containment. This level of performance demands a precise approach that includes material compatibility, appropriate torque sequencing and a strong understanding of system behavior.

Sealing failures often result from conditions that are preventable. Several contributing factors include:

- Low bolt load that fails to develop adequate sealing stress.

- Use of bolts with insufficient strength to maintain the load under service conditions.

- Gasket stress loss due to relaxation.

- Gasket relaxation, creep or cold flow, reducing gasket stress over time.

- Over-compression of the gasket, causing crushing or material extrusion.

- Loosening of bolts caused by system vibration.

- Gasket displacement from pressure surges such as water hammer.

- Uneven flange loading due to misalignment or improper torque sequencing.

- Chemical degradation when materials are not compatible with the process fluid.

- Mistakes during installation, such as reusing a gasket, incorrect torque or poor flange surface preparation.

These failure modes can result in leakage, compromised system integrity, safety hazards or costly downtime. Preventing them requires discipline and adherence to engineering best practices:

- Use the correct gasket material for the process conditions.

- Select bolts of appropriate grade and lubricate properly.

- Thoroughly clean and inspect flange surfaces for damage or warping.

- Apply bolt torque using a calibrated tool based on procedures or engineering analysis per ASME PCC-1: Pressure Boundary Bolted Flange Joint Assembly and retorque where applicable. Semi-metallic gaskets, like spiral wound gaskets and kammprofile gaskets, often do not require retorque.

- Train maintenance personnel and emphasize documentation and consistency.

Effective sealing depends as much on field execution as it does on material science. Precision, attention to detail and a strong safety culture are essential in every flange assembly.

Treat Gasket Sealing As A Strategic Component

Sealing products are not commodity items; they are engineered components that must be designed to meet application requirements. Gaskets and sealing systems serve as the last line of defense in maintaining containment, process integrity and operational continuity.

It is important to have a comprehensive understanding of the application requirements and conditions, as well as a thorough knowledge of the best available technologies when selecting a sealing solution for the connection of any piping system.

About the Author

About the Author