Sustainability is the practice of using resources in ways that avoid depletion and long-term damage. Sustainable fugitive emission reduction refers to implementing long-term, effective practices that minimize the release of unintended gas or vapor emissions from industrial equipment and processes. This approach aims to control emissions effectively while preserving future resources, ensuring that both environmental and operational goals can coexist for the long term.

Sealing solutions play a significant role in advancing sustainability beyond just reducing greenhouse gases (GHGs) and addressing climate change. High-quality gaskets and packing minimize leaks and emissions, protecting natural resources like water from contamination and reducing industrial impacts on surrounding ecosystems. By enhancing the reliability and safety of equipment, these solutions support broader sustainability goals, including biodiversity conservation, land preservation, and efficient water usage. Sealing technology contributes to a holistic approach to sustainability, aligning with efforts to safeguard the environment on multiple fronts.

By Angelica Pajkovic and Tim Goedeker, Teadit

What is Sustainability

The United Nations Framework Convention on Climate Change (UNFCCC) was first adopted in 1992 as a frame-work for international cooperation to combat climate change. The UNFCCC is responsible for creating and facilitating annual Conference of Parties (COPs) meetings focused on assessing global efforts to advance the key aims of limiting global warming, now typically referred to as climate change.

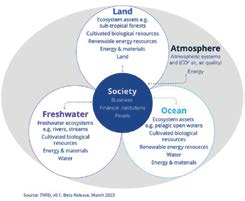

Although climate change has been a pressing subject for the last 32 years, the signing of the Paris Agreement in 2016 resulted in newly focused efforts to mitigate the negative impact of greenhouse gasses (GHGs), such as carbon dioxide (CO2) and methane (CH4). It is not surprising, therefore, that many individuals today associate the term ‘sustainability’ with GHGs and climate change. In reality, ‘sustainability’ encompasses a much broader scope of resource preservation, including the responsible use of land, water, and biodiversity, see Figure 1.1

Building on these climate-focused efforts, global organizations have worked to broaden the understanding of sustainability, recognizing it as a comprehensive framework that extends well beyond greenhouse gas reductions.

Fig. 1: A sustainable future includes air, land, freshwater, oceans, and society.

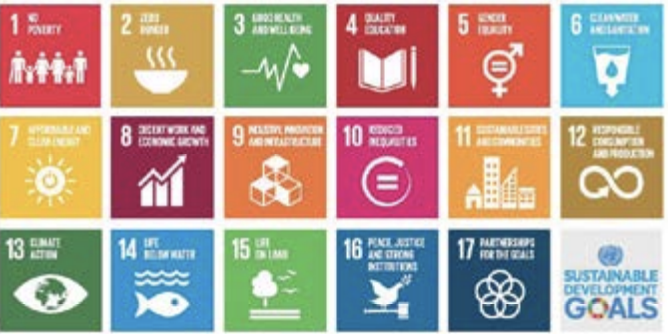

Fig. 2: UN Sustainability Development Goals (SDGs).

Global Conventions

For over a decade, the UN has devoted considerable effort to defining a sustainable world considerable effort to identifying what a sustainable world consists of. In 2012, 17 Sustainable Development Goals (SDGs), see Figure 2, were created to guide countries, businesses, and people on the journey to sustainability.2

While SDG #13, Climate Action, has received substantial global focus since the 2016 Paris Agreement at COP 21, other SDGs —such as SDG #6 (Clean Water and Sanitation), SDG #7 (Af-fordable and Clean Energy), SDG #9 (Industry, Innovation, and Infrastructure), and SDG #12 (Responsible Consumption and Production)—are equally critical to achieving comprehensive sustainability. Addressing these goals is essential for a balanced approach to reducing fugitive emissions and fostering sustainable practices.

For example, beyond climate change, the UN’s Convention on Biological Diversity (CBD), established in 1992 at the UN Earth Summit, highlights the importance of biodiversity in sustainable development. Its objectives, conserving biological diversity, sustainability using its components, and ensuring fair and equitable benefit-sharing from genetic resources, form the foundation for national strategies aimed at holistic, sustainable development.

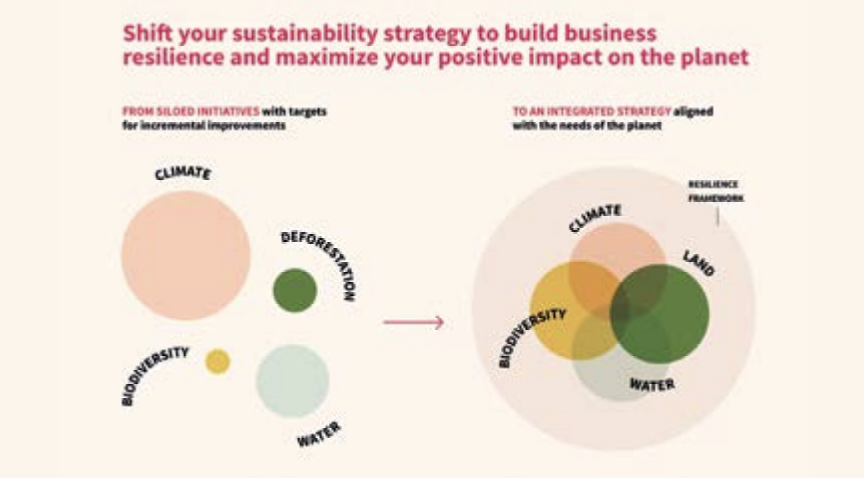

Implementing sustainable principles can take many forms, with no universal ‘one-size-fits-all’ solution. However, a comprehensive, integrated approach, see Figure 3, is more effective than a siloed strategy. By adopting a ‘cradle-to-grave’ lifecycle approach that considers all environmental factors, such as air, water, waste, land, and biodiversity, solutions become more robust and impactful.

This lifecycle-driven, multi-dimensional perspective ensures a broader sustainability goal, beyond just climate impact, is addressed. In contrast, the current tendency to evaluate sustainability through a single climate-focused lens limits the potential for developing truly holistic and environmentally aligned solutions.3 It is therefore important to utilize a multi-dimensional perspective when creating and using sealing solutions that directly impact the amount of emissions being released, such as on a valve or pipeline.

What Part do Gaskets and Packing Play?

Gaskets and packing solutions play a significant role in advancing sustainable industrial operations by focusing on reducing fugitive emissions from valves and flanged pipe connections. By preventing the escape of volatile organic compounds (VOCs) -organic chemical compounds whose composition makes it possible for them to evaporate at atmospheric temperature and pressure-, into the atmosphere, valve packing, such as Teadit’s 2848 or 2236, helps decrease the overall environmental impact of industrial processes. Proper packing selection results in fewer VOCs released into the atmosphere. Low-emission packings are certified to meet stringent requirements of leakage, with some as low as 2 parts per million (ppm).

Reduced emissions also mean lower health and safety risks for on-site personnel, as VOCs can be hazardous when inhaled or exposed over time. This reduction is crucial in minimizing the effect of industrial operations on climate change.

In addition to enhancing safety, these solutions help conserve valuable resources. Preventing VOC leaks avoids the wasting of the materials involved in the production and transport of process media, as well as the energy used to move and process it. By containing these elements within the system, sealing technologies like Teadit’s 913M spiral wound gasket maximize process efficiency and resource utilization, ultimately supporting the industry’s shift toward more sustainable practices.

Fig. 3: Integrated Sustainability Strategy Approach.

Ensuring All Aspects of the Solution are Sustainable

There are several solutions on the market today that arrest fugitive VOC emissions to well under 100 ppm. The next thing to consider is whether these solutions are being produced with the least amount of impact to the environment and the earth.

Facilities and operations should consider:

Water

- How much water is used in the pro-duction of the solutions?

- What can be done to reduce the freshwater use footprint?

- Can the amount of freshwater be reduced via recycling or can other types of water rainwater, treated wastewater – be used instead of freshwater?

Waste (liquid and solid)

- How much waste is generated in the production of the solutions?

- What can be done to reduce the footprint of waste generated?

- Can packaging be reduced to avoid excess waste?

Land (nature)

- How is nature (land primarily) impacted by the production of the solutions?

- If fugitive emission solutions use minerals from the earth, are there other minerals that could be used to produce an equivalent product with less impact on nature, i.e., less invasive mining or mineral capture processes.

In the ‘supply chain’ one should consider:

How water, waste, nature, and air/climate are impacted for each element in the supply chain. For example:

- How are the feedstocks used at the facilities produced?

- How are the feedstocks delivered to the facilities or operations?

- How are the facility’s products delivered to customers?

- What waste is generated by the customers from the use of the products?

To fully engage with sustainability efforts, manufacturers must implement efficient and responsible practices to address each of the considerations above.

Final Thoughts

Sustainability is not just the use and care of air, but also the use of water, the disposal of wastewater, the creation of waste, and care of nature and biodiversity. As the common goal is sealing for a safer and green-er tomorrow, it is important that the world begin to understand and adopt sustainable practices while manufacturing products, such as gaskets and packing, that aim to increase sustainability.

Proactive sealing manufacturers with increasingly efficient, reliable, and responsible processes should be constantly looking for ways to reduce their impact on the environment and the earth. Using the integrated, all of sustainability, lifecycle view when evaluating the benefit of fugitive emission mitigating solutions should be a consideration for all products.

REFERENCES

1. https://kpmg.com/xx/en/home/insights/2022/04/intro-ducing-the-tnfd-beta-framework.html

2. https://sdgs.un.org/goals

3. https://quantis.com/news/when-it-comes-to-biodiver-sity-businesses-are-at-a-loss/

About the Author

About the Author About the Expert

About the Expert