Natural gas (NG), primarily methane (CH4), plays a pivotal role in global energy. Its use as a primary energy source has steadily increased over recent decades due to its high hydrogen-to-carbon ratio, efficient combustion, and comparatively lower environmental impact. When measured on an energy basis, natural gas generates 50% fewer greenhouse gas (GHG) emissions compared to coal, and 30% less than heating oil.1

However, while natural gas has a smaller environmental impact relative to other fossil fuels, there remains significant potential to further reduce methane emissions throughout its supply chain. State-of-the-art sealing technologies will play a critical role in reducing these methane leaks.

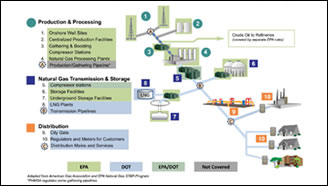

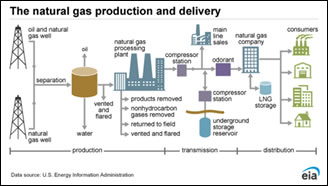

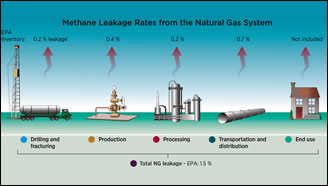

The transition to natural gas has been supported through the development of an extensive supply chain consisting of exploration, production, transportation, and distribution infrastructure, as well as gasification plants and end-users, Figure 1.

In the US, the Environmental Protection Agency (EPA) and Department of Transportation (DOT) have regulatory oversight throughout the NG supply chain. Figure 2 shows the areas of the supply chain covered by each agency.

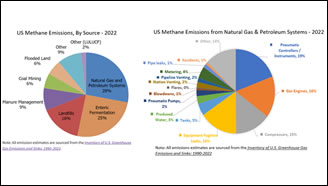

To contextualize the scale of methane emissions within the broader regulatory framework, it is essential to examine the sources contributing to their presence.

In 2022, U.S. methane emissions were estimated at approximately 800 million metric tons of CO2-equivalent (CO2e) based on a 100-year global warming potential (GWP). Of these emissions:

• 220 million metric tons originated from natural gas and petroleum systems, including:

• 43 million from pneumatic instruments (controllers),

• 35 million from gas engines,

• 35 million from equipment fugitive leaks,

• 32 million from compressors.

• The remaining emissions were attributed to sectors like livestock (200 million metric tons from enteric fermentation) and waste management (125 million metric tons from landfills).

Figure 1: Natural gas supply chain – Production through distribution. 3

Figure 1: Natural gas supply chain – Production through distribution. 3 Figure 2: Natural gas supply chain is regulated primarily by EPA and DOT. 3

Figure 2: Natural gas supply chain is regulated primarily by EPA and DOT. 3Understanding the composition and impact of methane is critical, as its significant contribution to emissions—particularly from natural gas and renewable natural gas systems— highlights the urgency of addressing its warming potential.

Methane’s Impact on the Atmosphere

Natural gas and renewable natural gas (RNG) are composed primarily of methane. Methane has a disproportionate impact on the atmosphere when compared to CO2.Although methane’s atmospheric lifespan (˜12 years) is shorter than CO2 (˜100 years), its warming potential is substantially higher. Over a 20-year period, methane has a Global Warming Potential (GWP) approximately 86 times greater than CO2, and 28 times over a 100-year span.This implies that 1 metric ton of methane leaked to the atmosphere has the same impact on the climate as 86 metric tons of CO2 over 20 years, and as 28 metric tons of CO2 over 100 years.

Given the significant climate impact of methane emissions, understanding the supply chains for natural gas, RNG, and hydrogen-blended natural gas is essential, as each of these energy sources plays a role in the overall emissions profile.

Supply Chain Overview

The production & processing steps for natural gas, RNG, and hydrogen blended natural gas are unique for each gas produced. However, the the supply chain, the transmission/ transportation through distribution steps, are nearly identical steps.

Comparing Natural Gas and Renewable Natural Gas (RNG) 8

While chemically identical, conventional natural gas and RNG differ in their production methods. Conventional NG is extracted from underground rock formations using traditional drilling and hydraulic fracking. RNG, also known as biomethane, is derived from organic waste through anaerobic digestion and gasification. After the organic matter has been broken down into methane and refined to pipeline-quality gas, it can be used in a similar manner to conventional natural gas.RNG’s environmental advantage lies in capturing methane that would otherwise escape from sources like landfills, sewage, and manure lagoons. However, RNG travels through the same infrastructure of piping and valves as NG, which is prone to leaks, and also emits CO2 at comparable levels when burned.

Figure 3: Renewable natural gas production schemes.9

Figure 3: Renewable natural gas production schemes.9 Figure 4: Leakage Risk along the Hydrogen Supply Chain.13

Figure 4: Leakage Risk along the Hydrogen Supply Chain.13Therefore, sealing technologies remain critical for both NG and RNG systems.

Hydrogen-Blended Natural Gas

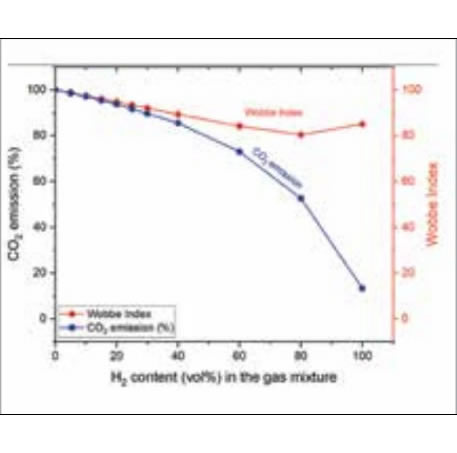

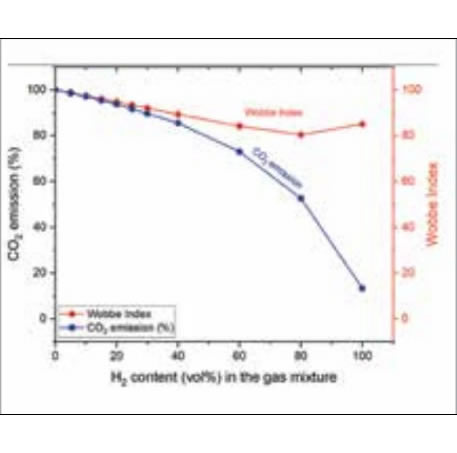

Hydrogen (H2) is often considered the most promising clean energy carrier to diversify and alleviate the dependence on fossil fuels, a key decarbonizing strategy. However, H2 is a small molecule that readily escapes and disperses into the atmosphere. H2 and CH4 are very different gases both physically and chemically. These differences present many challenges when considering use of the natural gas supply chain infrastructure for the transport and use of H2 as a combustion energy source. In general, a 20% hydrogen blend yields about a 7% reduction in combustion CO2 emissions compared with 100% natural gas, Figure 5.H2 leaks in the supply chain are mainly caused by defective seals or gaskets, venting, and purging, misalignment of valves, or failure of equipment. Leakage of H2 from vessels (during production and storage) and pipelines (during H2 leaks in the supply chain are mainly caused by defective seals or gaskets, venting, and purging, misalignment of valves, or failure of equipment. Leakage of H2 from vessels (during production and storage) and pipelines (during transport and end-use) is approximately 1.5 3.0 times higher than gaseous CH4. 11,12

Excessive CO2 and GHG emissions in the atmosphere raise significant concerns. Elevated CO2 levels contribute to the trapping of heat within the Earth's atmosphere, leading to a rise in global temperatures beyond the natural equilibrium of the carbon cycle. With climate tipping points anticipated in the coming decades, the substantially greater warming potential of methane over a 20-year period becomes increasingly critical.

Given the significant climate impact of methane emissions, understanding the supply chains for natural gas, RNG, and hydrogen-blended natural gas is essential, as each of these energy sources plays a role in the overall emissions profile.

Strategies to Reduce Fugitive Methane Emissions

Fugitive emissions, which occur at valves, flanged connections, pressure relief systems, tanks, and other components, represent a substantial source of methane leaks. Reducing fugitive emissions through the natural gas supply chain (including RNG and H2 blended NG) is some of the lowest-hanging fruits for reducing methane in the atmosphere. Figure: 5 Hydrogen blended with natural gas: A reduction in combustion CO2 emissions.10

Figure: 5 Hydrogen blended with natural gas: A reduction in combustion CO2 emissions.10 Figure 6: Teadit 913M Low Emission Spiral Wound Gasket.

Figure 6: Teadit 913M Low Emission Spiral Wound Gasket.Table 1 provides an indication of the desired fugitive emissions reduction target. The target is to reduce or eliminate 35 million metric tons CO2e (GWP 100 yr) per year of methane emissions from equipment fugitive leaks in the natural gas supply chain.

Investing in and implementing low-emission sealing technologies and performing routine leak monitoring and timely repair practices not only minimize environmental impacts but also delivers operational and financial benefits:

• Environmental Compliance: Reduced GHG emissions align with evolving regulations

• Product Loss: Preventing methane leaks reduces valuable product being lost to the atmosphere.

• Reduce Maintenance Costs: Decreases maintenance and replacement expenses.

• Emission Fees: Fees to operate will be lower as declared emissions are lowered.

• Reliability: Improved sealing extends the lifespan of critical infrastructure and enhances operational efficiency.

*GWP: Global Warming Potential factor.

*GWP: Global Warming Potential factor. Figure 7: Methane leaks in the Natural Gas Supply Chain.14

Figure 7: Methane leaks in the Natural Gas Supply Chain.14Sizable Emissions Reduction Potential

Implementing low emission sealing solutions can provide significant reductions in fugitive emissions in the oil and gas supply chain.This improves the environment, improves environmental compliance, and also reduces environmental fees; a win, win, win.In a hypothetical oil and gas operations facility with 1,000 flange pairs and 100 valves there would be approximately 28 metric tons/year of methane ‘leaked’ from flanges and valves into the atmosphere (fugitive emissions). This is approximately 800 metric tons/year CO2e. However, if these flange pairs and valves were fit with low-emission gaskets and packing, such asTeadit’s 913M spiral wound gasket and 2848 valve packing, less than 1 ton/year of methane would escape to the atmosphere.

This is a 96% reduction of fugitive methane emitted from equipment. Financially, this reduction of ‘leaked’ or ‘lost’ methane could yield a savings of at least $50,000 / year in product loss and environmental fees including the “waste emissions charge” (WEC) effective in 2025.

Advanced low-emission sealing solutions not only minimize emissions but also reduce the frequency of valve maintenance and replacements, extend the lifespan of supply chain components, and ensure smoother, more reliable operations. This improved reliability and durability directly translates into cost savings, making industrial low-emissions sealing solutions a vital investment for oil and gas infrastructure.

Example assumes: Flange and valve leaking at 10,000 ppm (leak rate of 0.026 metric tons/year per flange pair, 0.019 for valve), low leak gasket and valve packing leaking at 100 ppm (0.001 metric tons/year per flange pair, 0.0006 for valve). Methane GWP is 28 (100yr GWP).

REFERENCES

1. CO2e of various energy sources - https://www.eia.gov/environment/emissions/CO2_vol_mass.php2. EPA GHG data - https://www.epa.gov/ghgemissions/overview-greenhouse-gases

3. Figure 1 - Natural Gas Supply Chain - https://www.eia.gov/energyexplained/natural-gas/delivery-andstorage.php

4. CH4 GWP - https://www.cleanwisconsin.org/underthe-lens-the-truth-about-natural-gas/

5. GWP - https://www.epa.gov/ghgemissions/understanding-global-warming-potentials

6. Molecule diameter - https://en.wikipedia.org/wiki/Kinetic_diameter

7. Figure 2 - Natural Gas Supply Chain-EPA, DOT - https://www.whitehouse.gov/wp-content/uploads/2021/11/USMethane-Emissions-Reduction-Action-Plan-1.pdf

8. Content – Comparison of RNG w NG - https://diversegy.com/what-is-renewable-natural-gas/

9. Figure 3 – RNG production schemes - https://www.fortisbc.com/news-events/stories/5-exciting-ways-weare-getting-renewable-energy-from-waste

10. Figure 5 – H2 blending with Natural Gas - https://www.sciencedirect.com/science/article/pii/S036031992404597X#fig1

11. Content – Leaks - H2 blended with NG - https://scijournals.onlinelibrary.wiley.com/doi/epdf/10.1002/ese3.1861

12. Content – Leaks - H2 blended with NG - https://pubs.acs.org/doi/pdf/10.1021/acsenergylett.3c01098

13. Figure 4 – H2 supply chain - https://www.paconsulting.com/insights/reducing-the-cost-impact-of-hydrogenleakage-four-ways-to-address-fugitive-emissions

14. Figure 7 - Methane leaks in the NG Supply Chain - https://phys.org/news/2014-02-america-natural-gasleaky.html

Footnote:

Example assumes: Flange and valve leaking at 10,000 ppm (leak rate of 0.026 metric tons/year per flange pair, 0.019 for valve), low leak gasket and valve packing leaking at 100 ppm (0.001 metric tons/year per flange pair, 0.0006 for valve). Methane GWP is 28 (100yr GWP). About the Author

About the Author