As the world moves toward cleaner energy solutions, hydrogen production through electrolysis has emerged as a key player in reducing carbon emissions. Electrolyzers, which split water into hydrogen and oxygen using electricity, are at the heart of this process.¹ The efficiency and longevity of these systems are critically dependent on the integrity of their sealing gaskets, which play an essential role in ensuring the overall effectiveness and reliability of the process. Understanding the critical factors in sealing hydrogen is essential for minimizing fugitive emissions and providing safe, efficient containment.

By Angelica Pajkovic, Josmar Cristello, and Johannes Müller , TEADIT

Hydrogen’s impact on fugitive emissions

Achieving net-zero emissions by 2050 requires eliminating emissions not only during energy conversion but also during energy production. Fossil fuels such as natural gas, oil, and coal emit carbon dioxide (CO₂) when burned to produce energy. In contrast, hydrogen offers an alternative method of cleaner energy conversion, producing no greenhouse gas (GHG) emissions; however, it can emit nitrogen oxides (NOₓ) at high combustion temperatures if not adequately controlled.

Combustion: Similar to fossil-fuel combustion. Hydrogen combustion is much cleaner, as it produces no CO₂.

Electrochemical conversion (fuel cells): Fuel cells convert hydrogen into electricity through an electrochemical reaction. This process is more efficient than combustion and eliminates NOₓ emissions entirely.

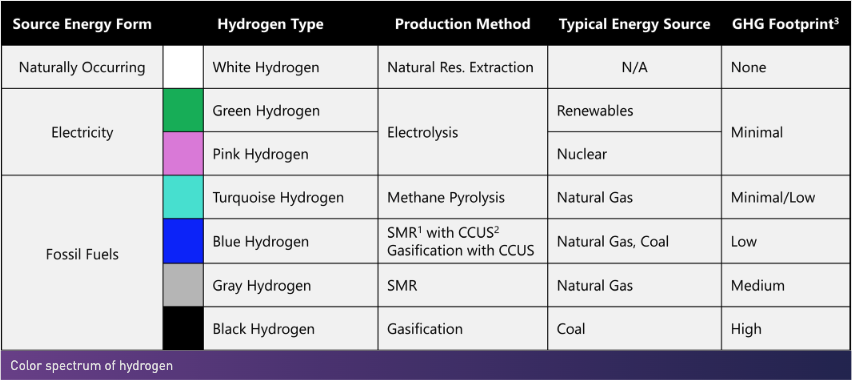

While GHG emissions from energy conversion are a concern, a far greater issue arises during hydrogen production. The industry categorizes hydrogen production methods based on their carbon footprint, using a color-coded spectrum to indicate environmental impact.

For hydrogen to contribute effectively to a net-zero future, industries must minimize fugitive emissions during production, transportation, and usage.

The challenge of hydrogen leakage

Despite its environmental benefits, hydrogen leakage presents significant challenges. With a Global Warming Potential (GWP₁₀₀) of approximately 12.8 ± 5.2,² hydrogen indirectly impacts climate dynamics by extending the atmospheric lifespan of methane, a potent greenhouse gas. Additionally, hydrogen leakage can contribute to tropospheric ozone formation and disrupt atmospheric energy balances.

From a practical perspective, hydrogen leaks pose safety risks due to its high flammability and extremely low ignition energy. Its nearly invisible flame in daylight complicates detection without UV/IR flame detectors or other specialized methods. Hydrogen is odorless and colorless, and because fuel-cell applications require high purity, adding odorants for leak detection is challenging.

Sealing hydrogen effectively, therefore, requires advanced gasket and packing solutions that prevent leaks, resist degradation, and maintain integrity under varying conditions.

Electrolyzers and their sealing needs

Electrolyzers play a crucial role in green hydrogen production by splitting water into hydrogen and oxygen using electricity. There are two main types:

Alkaline electrolyzers (AEL): Use a liquid electrolyte (KOH or NaOH). Known for durability, cost-effectiveness, and scalability—well suited for large-scale hydrogen production.

Proton exchange membrane (PEM) electrolyzers: Utilize a solid polymer membrane for compact designs, high efficiency, and rapid response to fluctuating power inputs. However, they require precious-metal catalysts (e.g., platinum, iridium), making them more expensive.

A critical component to ensuring efficiency in electrolyzers is the gasket. In an electrolyzer, cell frames separate individual cells, each housing an anode and a cathode. Positioned between each cell frame, gaskets prevent leaks, maintain system pressure, preserve hydrogen purity, maintain electrical insulation, and ensure overall efficiency.

Identifying the optimal gasket materials and manufacturing techniques is essential for ensuring a dependable seal, minimizing risks, and maintaining compatibility with the operational conditions of electrolyzers.

Sealing standards

The primary industry standards for testing sealing materials—such as ASME B16.20 and EN 13555 (for gaskets), and API 622, API 624, API 641, ISO 15848-1 (for packing and valves)—typically use methane or helium as test gases rather than hydrogen. However, hydrogen behaves differently due to its smaller molecular size, higher diffusivity, and unique permeation properties. Leak rates from helium testing are often used as a reference, but helium does not fully replicate hydrogen’s behavior. Direct hydrogen testing is essential for critical applications to ensure accurate leakage assessment and reliable sealing performance.

Choosing the right gasket material

Material selection

When considering the gasket material, polytetrafluoroethylene (PTFE) is widely recognized for its outstanding chemical resistance, thermal stability, insulating properties, and low-friction characteristics. Its near-total inertness to most chemicals makes it particularly well-suited for the demanding conditions within electrolyzers. However, not all PTFE gaskets are the same. Their performance can vary considerably depending on the manufacturing process and the quality of the raw materials. PTFE gaskets generally fall into three main categories:

Skived PTFE: Offers excellent chemical resistance. It is prone to creep and cold flow under load, leading to sealing failures over time.

Structured PTFE: Enhanced with fillers like glass microspheres, silica, or barium sulfate, reducing creep and improving mechanical stability while still maintaining a good chemical resistance.

Expanded PTFE (ePTFE): Manufactured with a microporous structure, it provides superior compressibility and resilience while maintaining excellent chemical resistance.

Compared to skived PTFE, both structured and expanded PTFE gaskets offer improved mechanical strength and reduced creep, making them more suitable for demanding environments within PEM and alkaline electrolyzers. Their enhanced properties ensure that the gaskets can withstand operational stresses over the long term, maintaining seal integrity and contributing to the overall efficiency and reliability of the hydrogen production process.

Furthermore, PTFE fluoropolymers provide excellent electrical stability across various environmental conditions, setting them apart from other insulating materials. For reference, pure PTFE exhibits superior electrical properties, with a high dielectric strength of around 24 kV/mm.

Sealing requirements

Each type of electrolyzer has specific sealing needs. For example, PEM electrolyzers require thin gaskets that provide high electrical insulation. Structured PTFE gaskets (e.g., Tealon™ TF 1570) provide excellent mechanical stability and maintain a reliable seal under limited bolt preload. In alkaline electrolyzers, the gasket must withstand exposure to caustic electrolytes like KOH. Expanded PTFE gaskets (e.g., TEADIT 24 SH) or structured PTFE (e.g., Tealon™ TF 1580) resist harsh chemicals while maintaining long-term sealing performance.

It is important to note that these are only a few examples of suitable materials for each type of electrolyzer. Sealing solutions are selected based on the specific requirements of each application, considering factors such as operating conditions, chemical exposure, pressure, and temperature demands. Each electrolyzer system undergoes a comprehensive material evaluation to ensure optimal performance and long-term durability.

Progressive innovation

Developing gaskets for electrolyzers is an ongoing process, and manufacturers are continuously testing and refining their products to meet the specific needs of different electrolyzer technologies. One of the key challenges in this field is ensuring that gaskets can withstand the operating temperatures and pressures typical of hydrogen production without losing their sealing capabilities.

Key considerations for achieving optimal sealability include:

Material compatibility with hydrogen, oxygen, and electrolytes

Mechanical durability to withstand compression and operational stresses

Resistance to creep and cold flow to maintain a long-lasting seal

Temperature and pressure resilience to prevent deformation and performance loss

Looking ahead

Hydrogen will play a vital role in the global energy transition, but its effectiveness depends on safe and reliable containment. Advances in sealing technology, including improved PTFE formulations and hydrogen-specific testing methods, will be essential in enabling the widespread adoption of hydrogen as a clean energy source. As industries scale up hydrogen production and the use of electrolyzers, high-performance gaskets and leak-prevention strategies will be crucial in ensuring efficiency, safety, and sustainability.

References

McKinsey & Company. (2024, January 10). Global Energy Perspective 2023: Hydrogen outlook.

Communications Earth & Environment, 3, Article 295 (2022).

US EPA. (2025, January 16). Understanding global warming potentials.