Developed in 1912 by Flexitallic in response to the increasing temperature and pressure demands of the refining operations of the day, the spiral wound gasket has now been a staple in the fluid sealing industry for over 100 years.

Across the spectrum of industrial applications, it is common to encounter spiral wounds. Despite their widespread use, surprisingly, the overall fundamentals of the technology have remained relatively unchanged over the last century.

Gasket Evolution

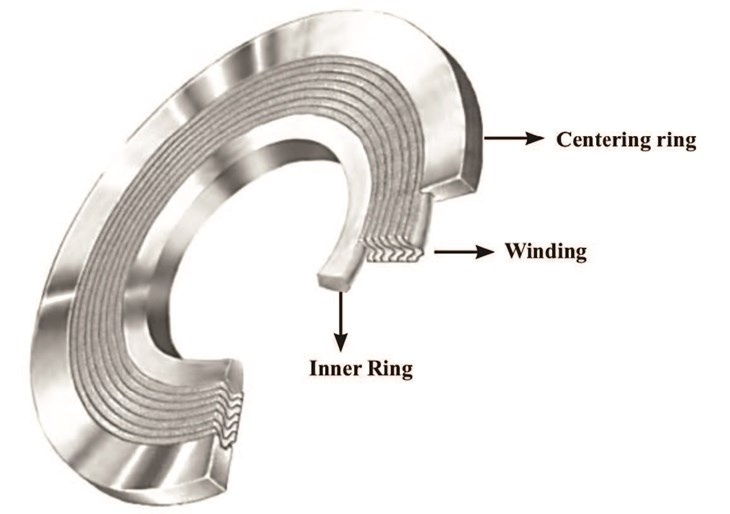

Unlike most products that need to regularly innovate and adapt over time to remain relevant, this stalwart has continued to perform without a dramatic overhaul. Perhaps this lack of innovation is due to the overall simplicity of the spiral wound gasket at a structural level. Alternating plies of metal and a soft filler material (commonly flexible graphite or PTFE) form the sealing element of a spiral wound gasket. Often this sealing ring is manufactured with a solid metal guide ring that serves to center the seal between standard pipe flanges. The gasket’s tendency to buckle radially inward under load led to the addition of a solid metal inner ring as well, which serves to eliminate the issue. However, this change was not officially incorporated into the industry’s governing standard until 2008.The fact that spiral wound gaskets have avoided the need to evolve at the macro level doe s not mean that the product has not undergone numerous iterations of microevolution in its life-time. Advances in the filler materials as well as the manufacturing process have led to important developments that continue to shape the future of spiral wounds today. The aforementioned addition of the inner ring was developed as a response to the industry’s need for a more reliable gasket. Changes like these have led to better performance and an overall better product, hands down.

Requirements and Standards

Spiral wound gasket manufacturing requirements have long been governed under the ASME B16.20 (Metallic Gaskets for Pipe Flanges) standard. The committee that develops and maintains this standard consists of a wide array of technical minds from across the industry, including manufacturers, system designers, and end-users. These men and women are tasked with analyzing industry trends to anticipate future needs, then using this information to develop standards that ensure that the end product meets and/or exceeds those needs. This is a tall order indeed, but for many years, this group has tried to meet the challenge head on.Prior to 2017, the B16.20 spiral wound gasket standard consisted of primarily dimensional requirements for the product. This meant that there was widespread variation in the quality and performance of spiral wound gaskets. Manufacturers were largely free to tinker with the ‘recipe’ as long as the resultant part was dimensionally accurate per the standard. Since the fastest way to grow market share is typically to offer a product that is less expensive than the competition, the rule of the day was cheaper is better. Since the filler material is typically less expensive than the winding metal, many spiral wound gaskets were ‘soft’ and easily compressible. In most cases, the sealing element of these gaskets could be compressed so that the flange face would contact the outer metal guide ring (a natural compression stop). This meant that the seal was then no longer effected by the sealing element itself, but rather by the much less reliable outer guide ring (a metal-to-metal interface).

Despite the perceived simplicity of spiral wound gasket technology, research and testing has shown that the ratio of winding metal to filler material drastically influences the overall performance of the gasket. A 2011 study performed by several members of Teadit’s Brazillian engineering team, including Global Technical Director, Jose Veiga, and David Reeves, the Senior Specialist for Bolting and Sealing Technology at Chevron Refining, investigated specifically how winding density impacts the gasket’s sealing performance. Their findings were conclusive, and this led some to rethink the traditional approach to manufacturing spiral wound gaskets, particularly in regard to achieving a tighter seal (an important consideration for many end users). However, the value of their research would not fully be realized at a standards level for several more years.

Fig1

Fig1Progressive Movement

A second study in 2017 (ASME PVP2017-65371) by Scott Hamilton, of Hex Technologies, and Joel Bauch and Jose Veiga, of Teadit, further sought to drive forward the conversation regarding performance testing of spiral wound gaskets. This paper laid out a process for effective testing and challenged the notion that achieving a desired amount of compression under a standardized load (as required per B16.20 paragraph 3.2.6) was an ineffective indicator for gasket performance. Some manufacturers had begun marketing specialized spiral wound gaskets with lower seating stresses or for low emissions performance, but why would these benefits not be standard? And without an agreed upon testing methodology, how could performance be qualified and quantified? These were the types of questions that the authors wanted to attempt to answer. The need for a more uniform spiral wound gasket was seemingly indisputable. Uniformity wasn’t the only concern though. The focus of the 2011 study was primarily concerned with meeting the stringent fugitive emissions demands of the EPA. Because the majority of fugitive emissions come from valve stems, the main focus of the industry for a number of years was developing more robust valve stem compression packings. Leak Detection and Reduction (LDAR) initiatives led to product innovation in that realm that have driven forward drastic improvements. Having slain the beast of valve stem packing, the industry turned its attention elsewhere. Gasket performance, especially spiral wound gaskets, continued to be an area of focus in this regard. Despite the developments of B16.20, prior to 2017, most traditional spiral wound gaskets manufactured to the standard would not meet fugitive emissions requirements today. Based on the testing performed by Veiga and Reeves in 2011, manufacturers understood that to control tightness, and by extension emissions, required careful control of the winding density and compressibility. This led most manufacturers to offer a specific line of spiral wounds marketed specifically for emissions reduction. Low emissions spiral wounds (‘low-e’ or ‘LE’ for short) may look like ‘standard’ spiral wound gaskets to the naked eye, but they incorporate a carefully controlled density as well as a filler that protrudes above the metal winding to produce optimum sealing performance at achievable sealing loads. However, such gaskets had to be specified by the customer specifically and came at a premium price. Fig2

Fig2The work done by these and others in the industry led to the adoption of a performance testing requirement in the 2017 revision to the B16.20 standard that now ensures that standard spiral wound gaskets will meet current EPA emissions requirements. As Veiga and Reeves discuss in their study paper (ASME PVP 2011-57556), “Field experience has shown that a leak can develop anywhere from a day after startup, to 15 years later after a major plant upset, and the severity of the leak can range anywhere from a PPM level violation of a consent decree to a major fire.” These are real concerns that end users face every day and pose not just a serious threat to their environmental responsibility and credibility, but more importantly to the safety and well-being of their employees. With so much on the line, end users need to trust that their critical components will work as expected every time. The current ASME B16.20 requirements mean that any customer who purchases a spiral wound should receive a controlled density gasket, without the need to specifically request (and pay for) a ‘low emissions’ part.

Looking Forward

The innovative work done by Veiga and Reeves sparked a steady stream of investigation into the relationship between spiral wound gasket construction and performance. More testing and studies have been completed over the last 10 years since their report was published. For example, a 2013 study (PVP2013-97008) by John McCarthy, of Dominion Energy, and Jerry Waterland and Dan Reid, of VSP Technologies, investigated the connection between spiral wound gasket compressibility and pressure classification. These and many others are pioneering a way towards better spiral wound gaskets and championing spiral wound testing standards that rival those of the American Petroleum Institute (API) testing for low emissions valves and valve stem packings that have been so successful in revolutionizing that industry. The future of spiral wound gasket technology is fertile ground for continued growth! About the Author

About the Author