Responsible for transforming raw materials into valuable products, the chemical industry is widely regarded as one of the most important economic sectors. The aggressive and often hazardous nature of the chemicals involved in these processes demands robust and reliable engineering solutions. One of the most critical components in ensuring the safety, efficiency, and environmental compliance of chemical processing plants is the sealing solutions.

The chemical industry is a complex amalgamation of processes and operations that use chemistry to manufacture various products. The scope of the raw materials used in these processes is vast, and they produce a variety of primary, secondary, and tertiary products, a distinction that indicates the distance of the product from the end user, primary being the most distant. The essential need for manufactured chemical products is, therefore, often unapparent, as each one is passed from one process to the next before emerging in the market.

In general, the chemical industry is divided into the following areas:

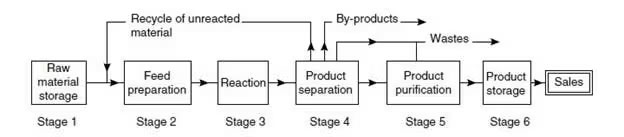

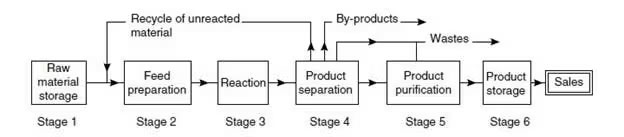

The production processes for each of these areas require unique assets and applications that can withstand the aggressive nature of the raw material as it moves from one state to the next, see Figure 1. For this reason, specially developed sealing solutions are required.

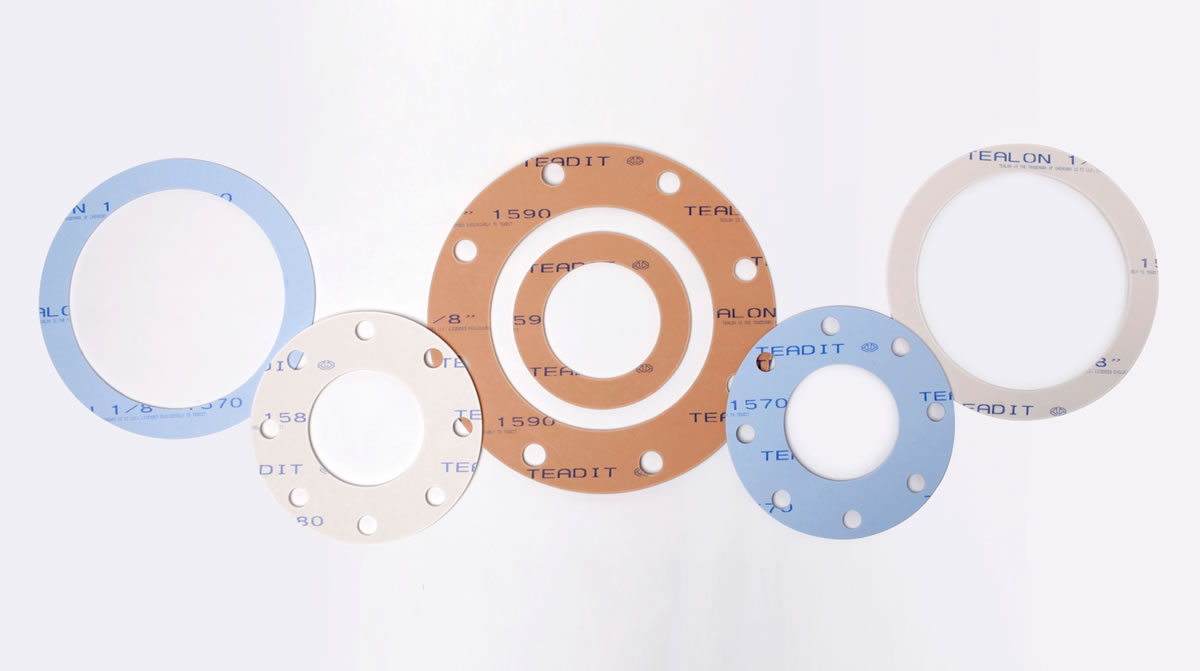

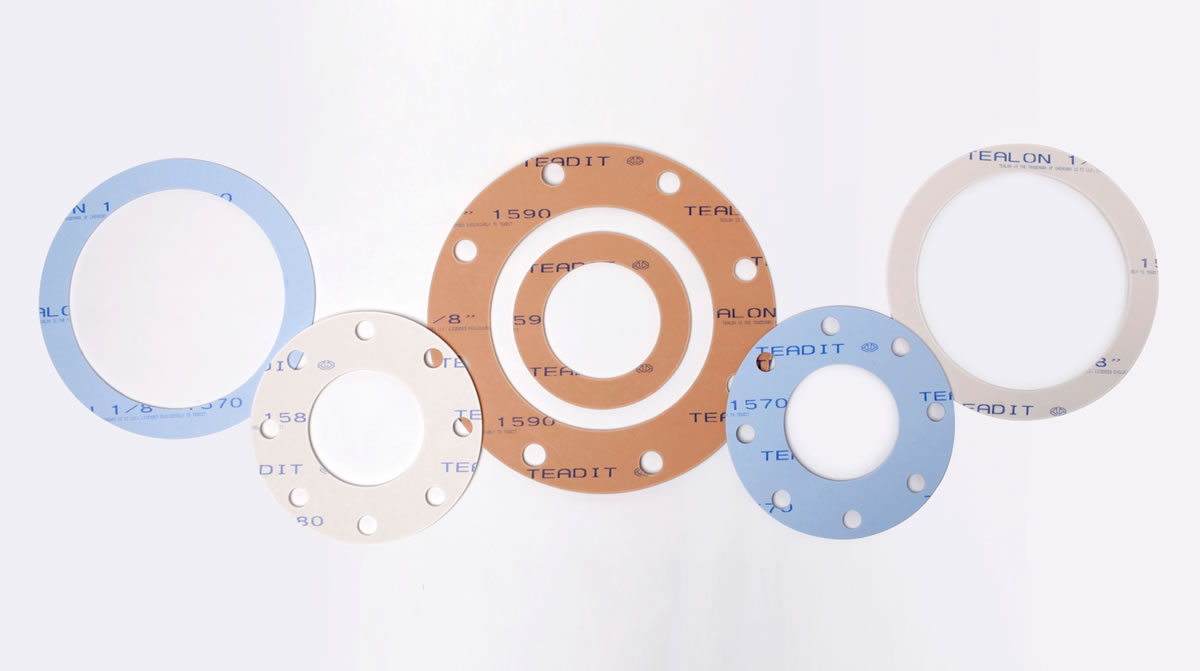

PTFE-based gaskets are often a reliable choice for sealing in chemical processing.

Beyond safety, seals are vital in maintaining process efficiency. They help regulate critical parameters such as pressure, temperature, and flow rates, directly influencing the consistency and quality of the production process. Seals ensure optimal operating conditions, enhance production efficiency, and reduce operational costs. Furthermore, by acting as a protective barrier, sealing solutions significantly extend the lifespan of equipment, minimizing wear and tear and reducing the need for frequent maintenance or replacement, ultimately contributing to long-term savings and increased operational reliability.

For example, when specific chemicals interact with some materials, the chemical can ‘attack’ the polymer bonds, degrading the polymer's properties. In some instances, chemicals can leach ingredients from the polymer, weakening it or stripping away essential mechanical properties. Other chemicals may permeate the polymer, leading to swelling. This swelling can be beneficial or detrimental, depending on the application. In some cases, the media may not impact the polymer at all. Instead, it may negatively impact one of the other raw materials utilized in the sealing material, leading to mechanical degradation and potential failure.

The wide variety of processes and chemical media used in the chemical industry means there is no ‘one size fits all’ choice regarding sealing. Most chemical plants utilize a wide variety of sealing solutions. These include:

In general, it is important to remember that every sealing solution has its own set of pros and cons. For example, elastomeric seals can create a seal at lower loads than most other seals. They also tend to be relatively inexpensive. That is great, right? Well, not so fast. They also crush at much lower loads than other seals, degrade more rapidly over time (especially at elevated temperatures), and exhibit a high level of relaxation, meaning they do not retain load well. They also vary greatly in their compatibility with various media based on the polymer.

PTFE-based seals, on the other hand, can withstand the most aggressive chemicals on the planet. They are generally considered soft, can conform to flange imperfections well, and have an indefinite shelf life. These are all great qualities and characteristics. The principal drawbacks of PTFE seals are the higher cost and the fact that PTFE, in its virgin form, is highly susceptible to creep relaxation.

Choosing the right sealing solution for an application requires carefully considering the many variables at play. There are times when a rubber seal is the right choice. Other times, it may be graphite, compressed fiber, or PTFE.

One of the most critical components in ensuring the safety, efficiency, and environmental compliance of chemical processing plants is the sealing solutions.

While HF process units are carefully monitored and controlled, unexpected problems can occur. Water introduced and remaining in the system during cleaning or maintenance activities or intrusions from leaks in other parts of the manufacturing process can lead to HF acid formation, which in turn leads to corrosion and, eventually, dangerous leaks. Areas within the process that provide the potential for pooling are at the most significant risk for acid corrosion. Therefore, a seal that does not fill gaps can lead to flange and sealing surface corrosion.

To address the challenges of properly and adequately sealing HF applications, manufacturers have designed unique sealing technologies. These seals marry different sealing materials and technologies together to take advantage of their various strengths and create a tandem seal that utilizes semi-metallic technologies with different fillers and facings. There are design variations between the type of metal construction (spiral wound, solid metal with serrations, corrugated metal, etc.) used for the primary seal in this type of application. Regardless of the selected construction style, it is highly recommended that a high-temperature, oxidation-inhibited grade of flexible graphite is specified as the primary sealing material due to its tight sealing performance.

Engineered solutions, like this example of an Echelon gasket for use in HF service, take advantage of the strengths of different materials and sealing technologies.

Engineered solutions, like this example of an Echelon gasket for use in HF service, take advantage of the strengths of different materials and sealing technologies.

Specialized gaskets for HF service often incorporate an expanded PTFE (ePTFE) secondary sealing element. PTFE is highly valued in harsh environments due to its near-universal chemical resistance. ePTFE is exceptionally compressible, allowing it to conform easily to flange surfaces that may be worn or corroded to completely fill and eliminate any gaps. There are several design variations, including thickness, core types, and adherence methods, that are used for secondary sealing. When choosing expanded PTFE for secondary sealing, specifying a low-creep material with uniform density is crucial.

In the complex and demanding chemical processing environment, sealing solutions are more than just a minor component—they are vital to the operation's safety, efficiency, and success. By understanding the challenges and employing suitable materials, designs, and maintenance practices, chemical processing plants can ensure their seals perform effectively, safeguarding their operations and the environment.

https://www.britannica.com/technology/chemical-industry

By Angelica Pajkovic and Chris Morris, Regional Sales Manager - Teadit

The chemical industry is a complex amalgamation of processes and operations that use chemistry to manufacture various products. The scope of the raw materials used in these processes is vast, and they produce a variety of primary, secondary, and tertiary products, a distinction that indicates the distance of the product from the end user, primary being the most distant. The essential need for manufactured chemical products is, therefore, often unapparent, as each one is passed from one process to the next before emerging in the market.

In general, the chemical industry is divided into the following areas:

- Basic chemicals

- Fine chemicals

- Specialty chemicals

- Inorganic chemicals

- Organic chemicals

The production processes for each of these areas require unique assets and applications that can withstand the aggressive nature of the raw material as it moves from one state to the next, see Figure 1. For this reason, specially developed sealing solutions are required.

PTFE-based gaskets are often a reliable choice for sealing in chemical processing.

Importance of Seals

Seals play a pivotal role in chemical processing. By preventing fluid, gas, and other material leaks, they ensure that nothing harmful infiltrates production or negatively impacts the surrounding environment.Beyond safety, seals are vital in maintaining process efficiency. They help regulate critical parameters such as pressure, temperature, and flow rates, directly influencing the consistency and quality of the production process. Seals ensure optimal operating conditions, enhance production efficiency, and reduce operational costs. Furthermore, by acting as a protective barrier, sealing solutions significantly extend the lifespan of equipment, minimizing wear and tear and reducing the need for frequent maintenance or replacement, ultimately contributing to long-term savings and increased operational reliability.

Seal Type and Material Selection

A seal's chemical compatibility with system fluids is, therefore, essential for achieving reliable and durable performance. As the way polymers and other raw materials used in seals react with fluid chemicals varies greatly, the selection process can be highly challenging, particularly when relying solely on chemical compatibility charts.For example, when specific chemicals interact with some materials, the chemical can ‘attack’ the polymer bonds, degrading the polymer's properties. In some instances, chemicals can leach ingredients from the polymer, weakening it or stripping away essential mechanical properties. Other chemicals may permeate the polymer, leading to swelling. This swelling can be beneficial or detrimental, depending on the application. In some cases, the media may not impact the polymer at all. Instead, it may negatively impact one of the other raw materials utilized in the sealing material, leading to mechanical degradation and potential failure.

The wide variety of processes and chemical media used in the chemical industry means there is no ‘one size fits all’ choice regarding sealing. Most chemical plants utilize a wide variety of sealing solutions. These include:

- Elastomeric: Made from a wide array of different polymers, such as NBR (Nitrile Butadiene Rubber), EPDM (Ethylene Propylene Diene Monomer), Silicone, Neoprene, FKM, and more; these seals can be used in a variety of applications in the form of gaskets, o-rings, and specialty molded seals.

- Compressed Fiber: Made from a combination of an elastomeric binder and synthetic, organic, and/or inorganic fibers, along with other ingredients, these materials are often used in a wide variety of generalized services.

- Flexible Graphite: Chemically expanded and then manufactured into rolls or sheets, graphite seals offer excellent chemical resistance while also handling higher temperatures than seals containing rubber. Many graphite sealing materials also feature layers of metallic reinforcement to make them stronger and allow them to resist higher operating pressures.

- PTFE (Polytetrafluoroethylene): Perhaps the most commonly used material in chemical processing sealing solutions, PTFE offers exceptional chemical resistance to even the most aggressive media.

- Metal: More common in applications with extremely high temperatures and pressures, metal-based sealing solutions still have their place in chemical processing plants. Made entirely of metal or a combination of a metal carrier element with a softer sealing element (like graphite or PTFE), these seals are utilized to some degree in nearly every industrial manufacturing plant worldwide.

Pros and Cons

With so many options for sealing solutions, choosing which is best suited for a particular application can be challenging. Due to the aggressive nature of many raw materials used in chemical processing facilities, the margin for error is low, and safety is paramount. The ideal solution should offer safe and reliable performance over the life of the process until the next scheduled maintenance event. Working closely with a knowledgeable sealing product manufacturer or supplier can be an asset to any chemical plant.In general, it is important to remember that every sealing solution has its own set of pros and cons. For example, elastomeric seals can create a seal at lower loads than most other seals. They also tend to be relatively inexpensive. That is great, right? Well, not so fast. They also crush at much lower loads than other seals, degrade more rapidly over time (especially at elevated temperatures), and exhibit a high level of relaxation, meaning they do not retain load well. They also vary greatly in their compatibility with various media based on the polymer.

PTFE-based seals, on the other hand, can withstand the most aggressive chemicals on the planet. They are generally considered soft, can conform to flange imperfections well, and have an indefinite shelf life. These are all great qualities and characteristics. The principal drawbacks of PTFE seals are the higher cost and the fact that PTFE, in its virgin form, is highly susceptible to creep relaxation.

Choosing the right sealing solution for an application requires carefully considering the many variables at play. There are times when a rubber seal is the right choice. Other times, it may be graphite, compressed fiber, or PTFE.

One of the most critical components in ensuring the safety, efficiency, and environmental compliance of chemical processing plants is the sealing solutions.

A Look at HF Production – A Case Study

Perhaps one of the most dangerous and aggressive processes in chemical processing can be hydrogen fluoride production. If incompatible materials react, they can cause corrosion, mechanical weakening, and other undesirable interactions. Therefore, it is essential to devote significant time to not only the seal material but also the seal itself. For example, deciding which gasket type to use for sealing in HF production requires careful consideration.While HF process units are carefully monitored and controlled, unexpected problems can occur. Water introduced and remaining in the system during cleaning or maintenance activities or intrusions from leaks in other parts of the manufacturing process can lead to HF acid formation, which in turn leads to corrosion and, eventually, dangerous leaks. Areas within the process that provide the potential for pooling are at the most significant risk for acid corrosion. Therefore, a seal that does not fill gaps can lead to flange and sealing surface corrosion.

To address the challenges of properly and adequately sealing HF applications, manufacturers have designed unique sealing technologies. These seals marry different sealing materials and technologies together to take advantage of their various strengths and create a tandem seal that utilizes semi-metallic technologies with different fillers and facings. There are design variations between the type of metal construction (spiral wound, solid metal with serrations, corrugated metal, etc.) used for the primary seal in this type of application. Regardless of the selected construction style, it is highly recommended that a high-temperature, oxidation-inhibited grade of flexible graphite is specified as the primary sealing material due to its tight sealing performance.

Engineered solutions, like this example of an Echelon gasket for use in HF service, take advantage of the strengths of different materials and sealing technologies.

Engineered solutions, like this example of an Echelon gasket for use in HF service, take advantage of the strengths of different materials and sealing technologies. Specialized gaskets for HF service often incorporate an expanded PTFE (ePTFE) secondary sealing element. PTFE is highly valued in harsh environments due to its near-universal chemical resistance. ePTFE is exceptionally compressible, allowing it to conform easily to flange surfaces that may be worn or corroded to completely fill and eliminate any gaps. There are several design variations, including thickness, core types, and adherence methods, that are used for secondary sealing. When choosing expanded PTFE for secondary sealing, specifying a low-creep material with uniform density is crucial.

Solutions to Sealing Challenges

Understanding which sealing solution will provide the optimal seal can prevent costly downtime, reduce maintenance needs, and extend the life of equipment, making it an essential investment for any chemical processing facility. Addressing these challenges requires a combination of material science, engineering expertise, and regular maintenance practices:- Material Selection: Choosing a suitable material is crucial. Seals made from PTFE or other specialized elastomers are often used for chemical compatibility due to their resistance to a wide range of chemicals. Materials like graphite or metal seals may be required for high-temperature applications.

- Advanced Design: Modern seals are designed to accommodate the specific conditions of chemical processing environments. This includes using composite materials, special coatings, and advanced geometries that enhance sealing performance and durability.

- Regular Maintenance and Monitoring: Implementing a proactive maintenance program can help identify wear and tear before it leads to failure. This might include regular inspections, performance monitoring, and replacing seals as part of routine maintenance schedules.

- Custom Solutions: In some cases, like the previous example of HF production, standard seals may not be sufficient. Custom-designed seals can be tailored to the specific requirements of a chemical process, ensuring optimal performance and longevity.

- Training and Education: Ensuring plant personnel are trained in adequately installing, maintaining, and replacing seals can prevent many common issues. Knowledgeable operators can spot potential problems early and take corrective action before a seal fails.

In the complex and demanding chemical processing environment, sealing solutions are more than just a minor component—they are vital to the operation's safety, efficiency, and success. By understanding the challenges and employing suitable materials, designs, and maintenance practices, chemical processing plants can ensure their seals perform effectively, safeguarding their operations and the environment.

References

"https://chemicalprojects.wordpress.com/2013/12/15/the-anatomy-of-a-chemical-manufacturing-process/https://www.britannica.com/technology/chemical-industry

About the Expert

About the Expert About the Author

About the Author