-

Sheets and Gaskets

-

1500

Virgin PTFE Sheet

-

1525

25% Glass Filled PTFE

-

TF 1550

Mechanical Grade PTFE Sheet

-

TF 1560

Restructured PTFE for Monomer Service

-

Tealon TF 1570

Restructured PTFE with Glass Spheres

-

Tealon TF 1580

Restructured PTFE with Barium Sulfate

-

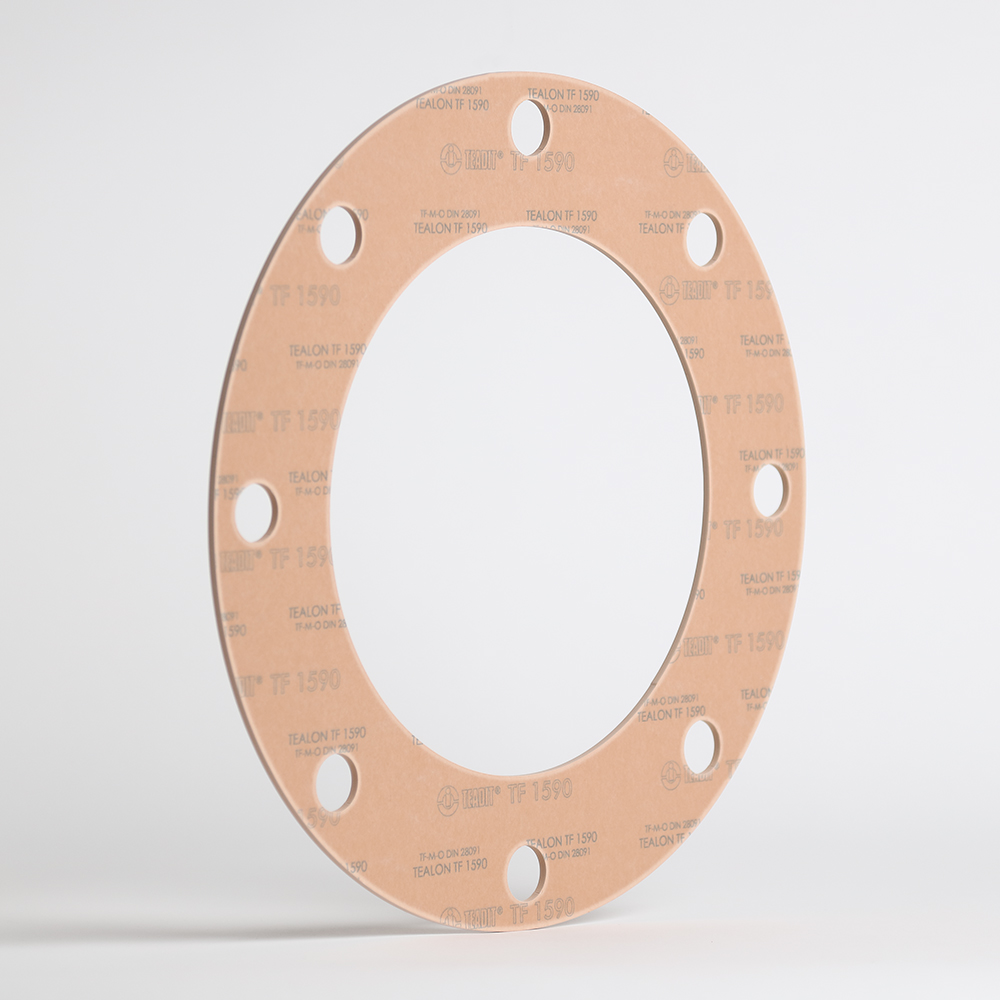

Tealon TF1590

Restructured PTFE with Silica

-

TF 1572 SAN

Restructured PTFE and Glass Spheres

-

Teadit® Origin™ RC510 Gasket

Rail Car Gasket

-

-

Chemical Compatibility Chart