| Temperature ºF (ºC) | |

|---|---|

| Minimum | -464 (-240) |

| Maximum | 840 (450) |

| Steam | 1202 (650) |

| Pressure psi (bar) | |

|---|---|

| Static | 5800 (400) |

| pH | |

|---|---|

| Minimum | 0 |

| Maximum | 14 |

| Temperature ºF (ºC) | |

|---|---|

| Minimum | -464 (-240) |

| Maximum | 840 (450) |

| Steam | 1202 (650) |

| Pressure psi (bar) | |

|---|---|

| Static | 5800 (400) |

| pH | |

|---|---|

| Minimum | 0 |

| Maximum | 14 |

| Size | Ft/Lb | 116.3 | 54 | 30.2 | 19.9 | 13.9 | 10.1 | 8 | 6.3 | 5.2 | 3.6 | 2.7 | 2.2 |

| Inch | 1/8 | 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 3/4 | 7/8 | 1 | |

| Package | 1 Lb (0.5kg) | 2 Lbs (1kg) | 5 Lbs (2kg) | 10 Lbs (5kg) | |||||||||

Tests realized by Yarmouth Research and Technology Maine – USA

Fire Test

Objective

Qualify packing Style 2000IC for fire resistance when applied to valves subjected to direct flame.

Test Procedure

API STANDARD 589 – SECOND EDITION

Test Parameters

Exposure time to fire – 40 minutes;

Temperature in the valve body up to 679ºC;

Allowable Leakage, pressures of the test and measurements done according to table below.

Conclusion

Packing Style 2000IC has successfully completed the test easily reaching the requirements of this standard.

| Parameters | Leaks(ml/min) | Pressure | |

|---|---|---|---|

| Measured | Allowable | (psiq) | |

| During the 2 minutes pretest hydrostatic | 0.0 | 0 | 537 |

| During firing and cooling | 0.0 | 60 | 567 |

| During the low pressure test after firing | 0.0 | 3 | 50 |

| After the closing and opening operation | 0.4 | 60 | 537 |

Leak detection method

“EPA method 21”.

Test Procedure

ARCO Fugitive Emission Test Specification.

Test Parameters

3 thermal cycles at room temperature and at 177ºC;

Leakage measurements are performed before and after each thermal cycle and at each 100 cycles of the shaft;

Test pressure: 645 psig (45 Kgf/cm2);

Test Fluid: Foxboro OVA128 (99% methane);

Maximum allowable leakage: 100 PPMv (if the leak allowed exceeds 100 PPMv, the sobreposta must be adjusted).

Conclusion

Packing 2000IC has successfully completed the test with 5 adjustments during the 3,500 cycles while maintaining leakage under 100 PPMv.

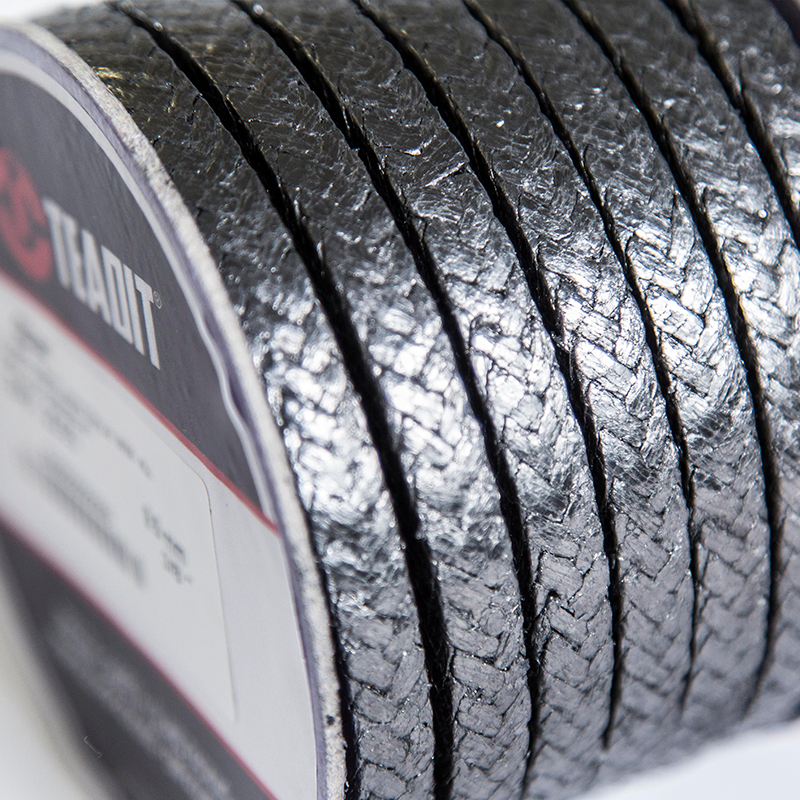

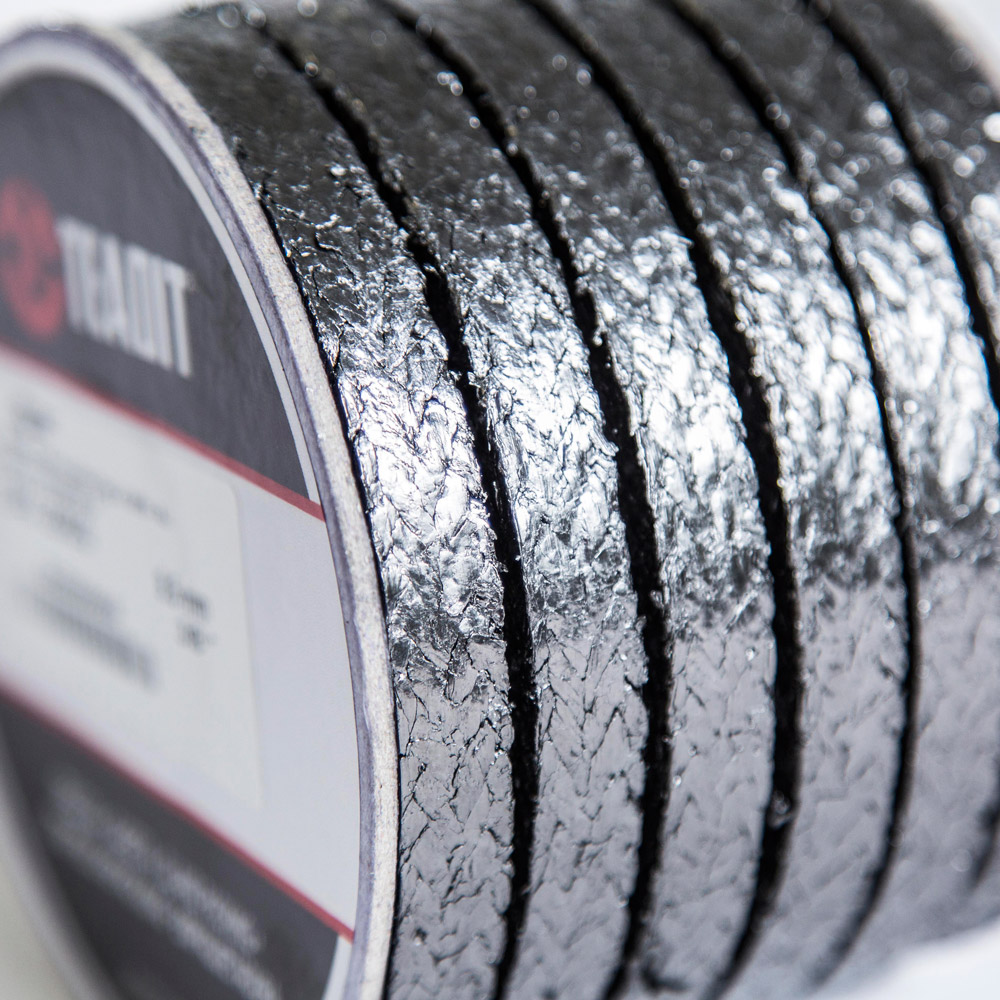

Flexible Graphite with Inconel Wire, Low Emission

Valve Stem Packing

Flexible Graphite with Carbon Corners

High Temperature and High Pressure Valve Stem

Flexible Graphite

Carbon Yarn, Graphite Filled

Carbon Yarn, PTFE Impregnated

Graphite Yarn, Graphite Filled

Developing A Special Camprofile Gasket For a Pressure Vessel

Style 2007 in Chemical Slurry

Thermic Fluid Case History

Dual Packing Combination Kit in Sugar Industry

2235 in Steam Application Case History

Teadit 24SH in Chemical Processing

Teadit Camprofile Gasket in Chemical Processing

ETP Copper Process Case History

CMS Plant Case History

2774 Harsh Chemicals Case History