In the demanding environment of petrochemical plants, minor inefficiencies can lead to major operational and financial consequences. A valve leak, specifically, can result in the release of hazardous chemicals, posing severe risks to worker safety and significant losses in energy efficiency. If left unaddressed, these leaks can result in costly downtime and potential regulatory penalties, impacting the plant’s operations.

Understanding how to effectively mitigate the negative consequences of a valve leak, and implement a viable solution is, therefore, essential to ensure that the plant operates

as efficiently as possible.

In ethylene production, which involves high temperatures and pressures, valves are crucial for ensuring the precise control of process variables to optimize yield and maintain operational safety. These valves manage the flow of feedstocks, control the temperature and pressure within reactors, and isolate sections of the system for maintenance and safety purposes.

In this case, the traditional die-formed graphite ring packing used to seal the valve proved inadequate under the highpressure conditions required for production. The use of the unfit packing led to leaks that escalated maintenance costs and posed severe safety risks.

The leaking steam also had economic consequences, as the method used to create the steam included burning hydrocarbon (typically, natural gas or fuel oil), which is costly to produce.

While the plant’s preventative maintenance program involved regular replacement of the packing rings, this action failed to resolve the issue. The next consideration was the costly and extensive process of replacing all 1,520 affected valves. Faced with the prospect of a disruptive valve replacement process, the large petrochemical plant sought a more effective solution.

Understanding how to effectively mitigate the negative consequences of a valve leak, and implement a viable solution is, therefore, essential to ensure that the plant operates

as efficiently as possible.

By Angelica Pajkovic and Roberto Araujo – Teadit

The Challenge

A large petrochemical plant faced significant challenges due to leakages in the superheated steam valves within its Ethylene unit.In ethylene production, which involves high temperatures and pressures, valves are crucial for ensuring the precise control of process variables to optimize yield and maintain operational safety. These valves manage the flow of feedstocks, control the temperature and pressure within reactors, and isolate sections of the system for maintenance and safety purposes.

In this case, the traditional die-formed graphite ring packing used to seal the valve proved inadequate under the highpressure conditions required for production. The use of the unfit packing led to leaks that escalated maintenance costs and posed severe safety risks.

The leaking steam also had economic consequences, as the method used to create the steam included burning hydrocarbon (typically, natural gas or fuel oil), which is costly to produce.

While the plant’s preventative maintenance program involved regular replacement of the packing rings, this action failed to resolve the issue. The next consideration was the costly and extensive process of replacing all 1,520 affected valves. Faced with the prospect of a disruptive valve replacement process, the large petrochemical plant sought a more effective solution.

Packing Evaluation

After concluding that the current packing challenges would not be solved through the established maintenance program, the plant sought expert advice to address the issue.An engineering team conducted a thorough evaluation of the situation.

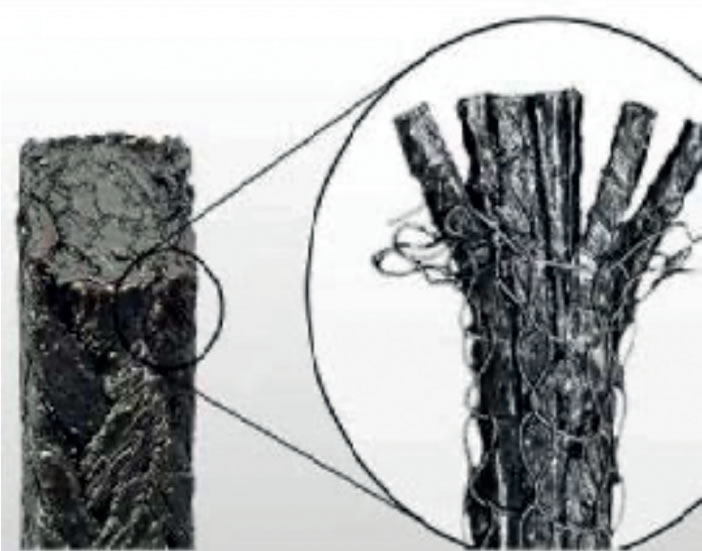

Upon assessment, the team recommended switching to a higher-pressure, metal-reinforced graphite packing style. This packing style comprises layers of high purity with oxidation inhibitor flexible graphite tape plied into compact strands; each filament is reinforced with an Inconel® wire jacket. The strands are then square braided to form a dense yet malleable packing. This provides mechanical stability and prevents extrusion. Its advanced construction ensures effective leakage control and high integrity in steam service, promising a superior seal when compared to the previously used standard graphite packing.

Implementation and Results

A trial was conducted on 384 valves of various sizes, ranging from ½” to 16”, to ensure that the improved packing would meet the requirements. The success of the packing was evaluated using the STAMP (Size, temperature, application, material/media, pressure) evaluation system.The new packing performed exceptionally during the trial, proving an effective solution for the plant’s leakage issues. Consequently, the plant approved using the new packing for all valves.

Outcomes

Implementing a packing equipped with a reinforcing metal, such as Inconel® wire, eliminated the need to replace all the valves, significantly reducing maintenance and repair costs. The plant achieved savings of over USD 2.5 million, highlighting the success of the new valve-packing solution in enhancing operational efficiency and safety.This strategic upgrade not only improved the plant’s performance but also set a new standard for cost-effective maintenance practices.

Before the use of reinforced packing.

Before the use of reinforced packing. After the use of reinforced packing.

After the use of reinforced packing. Close-up view of Teadit’s 2235 style packing. It is fabricated with Individual strands of graphite tape reinforced with an Inconel wire.

Close-up view of Teadit’s 2235 style packing. It is fabricated with Individual strands of graphite tape reinforced with an Inconel wire.- S: Ensured the size of the packing material is suitable for the service.

- T: Ensured it was suitable for the temperature.

- A: Ensured it was appropriate for the application. Different packing styles are better for different types of applications. For example, some packing can be good for a pump but not ideal for a control valve. The valve stuffing box and stem were also analyzed for corrosion; some packings are better at sealing corroded surfaces than others.

- M: media: Ensured the packing can seal a gas, liquid, or two-phase flow.

- P: pressure. Ensured the packing could withstand the pressures. Operators must also consider how tight a stud should be to create a seal at that pressure.

In addition to the STAMP analysis, rigorous installation practices, such as the assembly torque, were communicated to the operators to ensure that the valve packing could operate as efficiently as possible.

About the Author

About the Author About the Expert

About the Expert