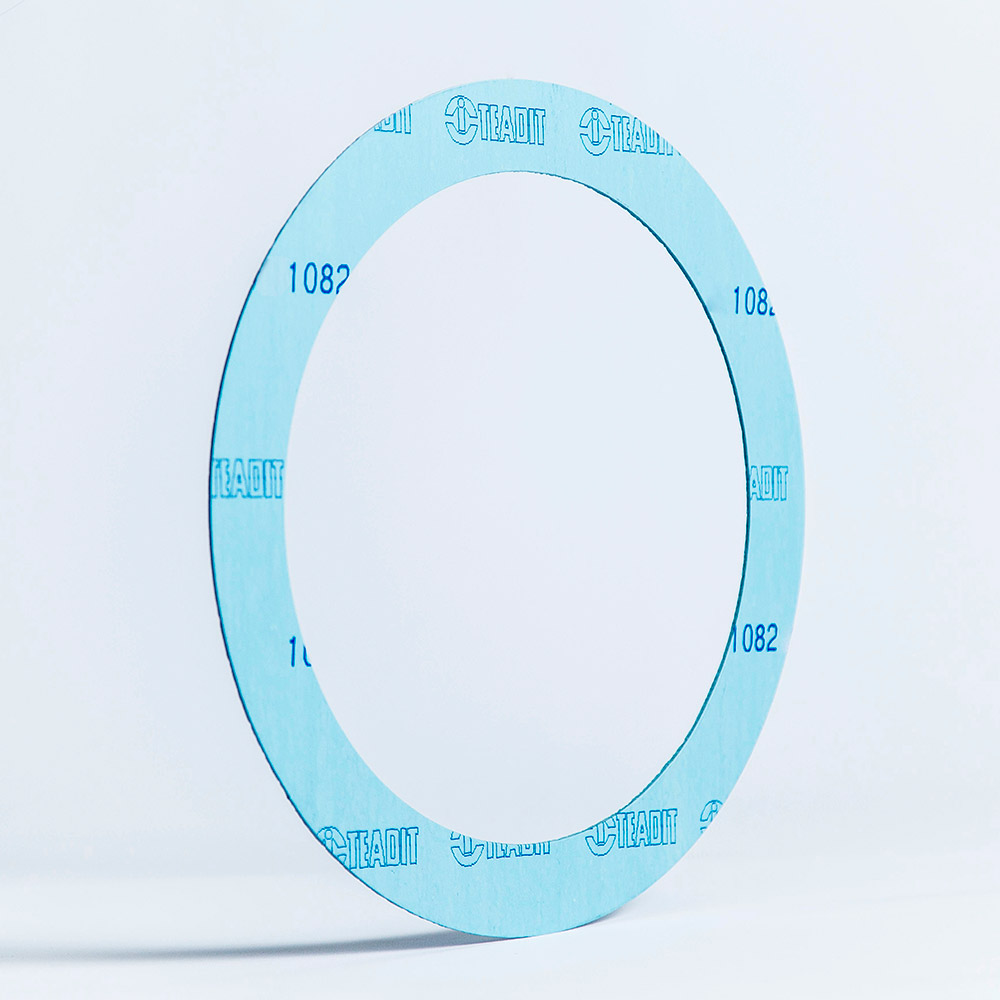

Tealon TF 1580Restructured PTFE with Barium Sulfate

Description and ApplicationsTealon TF 1580 is filled with barium sulfate and is suitable for strong caustic fluids. It meets FDA conformance for service within food and pharmaceutical applications. 1580 can be used in a wide range of applications due to its vast resistance to most chemical products. It is compatible with strong acids along with strong caustics, making it the most diverse material within the Tealon family. With the off-white color of 1580, this material is also suitable for processes where contamination is not tolerated. Tealon 1580 meets and has been approved by BAM for oxygen service.

Approvals: DVGW — TA-Luft — FDA — BAM — Chlorine Institute